Contact immediately

Contact immediately

Automatic CNC Paper Tube Cutter

Efficient Automated Production

Fully automates feeding, cutting, and discharging with no manual intervention, supporting continuous high-speed production to significantly boost efficiency.

Automatically sorts material heads and tails, eliminating manual sorting steps and directly connecting to subsequent production processes to optimize workflow.

Integrates intelligent cutting algorithms for precise control of cutting length, ensuring low error rates and consistent product quality.

One-click startup for simple operation, reducing operational complexity and saving training costs.

Flexible Cutting, Reduced Waste

Adopts a CNC single-blade design, allowing users to freely adjust cutting width to fit different specification requirements.

Supports combined cutting of multiple lengths to maximize material utilization and minimize waste.

Frequently used specifications can be saved for quick recall, making it especially suitable for production scenarios requiring frequent size changes.

Intelligently senses cutting force to protect the blade while ensuring cutting quality, extending machine service life.

High-Precision Cutting, Quality Guaranteed

Delivers precise cutting dimensions with smooth, burr-free ends, enhancing the overall quality of finished products.

Automatically senses paper tube thickness and intelligently adjusts cutting depth to ensure stable cutting of paper tubes with different materials and thicknesses.

Equipped with an automatic lubrication system to reduce mechanical wear and extend equipment lifespan.

Easy Operation & Maintenance

Features an intuitive human-machine interface, enabling operation without professional training.

Automatic fault diagnosis with visual photo prompts for quick troubleshooting and repairs.

One-click reset function for easy restoration of initial settings, reducing debugging time.

Remote monitoring and control capabilities allow real-time production status tracking anytime, anywhere, improving management efficiency.

Stable, Durable & Worry-Free After-Sales

Adopts the Mitsubishi CNC system, boasting mature technology and stable, reliable operation.

Comes with a 1-year full machine warranty and lifelong after-sales service, ensuring comprehensive support.

Automatic lubrication system reduces manual maintenance needs and extends equipment service life.

Multi-Industry Application & Wide Recognition

Equipped with an automatic tube feeding lifting platform for quick switching between different-sized cores, improving changeover efficiency.

Automatically calculates blade working time and cuttable quantity, with a rationally designed feature set to meet diverse production needs.

Widely used in industries such as adhesive tape, paper tubes, labels, stationery, printing, textiles, medical supplies, and paper can packaging, with excellent customer feedback.

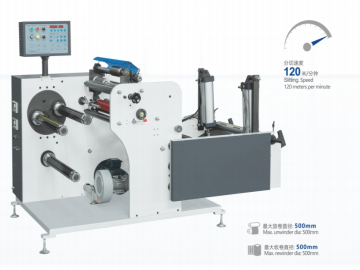

Product Parameters

|

3103 CNC Paper Tube Cutter Parameter Table |

|||

| Technical Parameters | Specifications | Control System | Brands/Models |

| Tube Cutting Length | 1m, 1.3m, 1.6m, 1.8m, 2m, 2.5m, 3.2m | PLC Controller | Imported Mitsubishi System |

| Tube Cutting Diameter | 25-200mm | HMI (Human-Machine Interface) | Weintek |

| Number of Cutting Blades | 1 set | Program Version | 2025 |

| Cutting Table Moving Speed | 35 m/min | Frequency Converter | |

| Cutting Method | Paper tube rotates, cutter shaft remains static |

Executive Devices | Chint Products |

| Loading/Unloading Method | Automatic loading and unloading | Signal Components | Chint Products |

| Clamping Method | Automatic pneumatic chuck | Pneumatic Components | Chint Products |

| Operating Personnel | 1 person | Servo Motor | HONGBAODA |

| Feeding Method | Pneumatic cutter | Moving Screw | Jingheng |

| Minimum Slitting Width | 1mm | Moving Rail | Jingheng |

| Input Power | 380V three-phase four-wire | Cutter Material | Tungsten Steel |

| Cutting Thickness | 1mm-18mm | Included Accessories | |

| 1.3M Specification Dimensions | 3500mm*1600mm*1300mm | Cutting Blades | 2 pieces |

| 1.3M Total Weight | 1000KG | Application Tools | 1 set |

| 1.3M Total Power | 3.5KW | ||

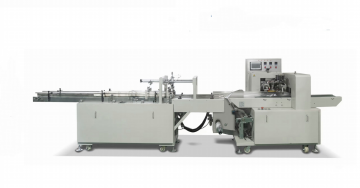

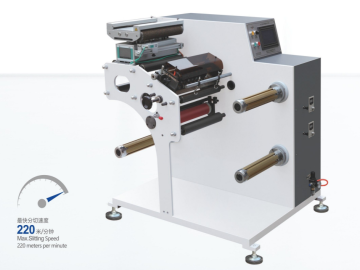

Product Display

our factory

Get in touch

We're Ready To Assist You Anytime