Contact immediately

Contact immediately Custom Automated Cutting Solutions for Factories and Suppliers

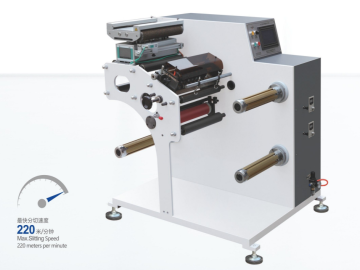

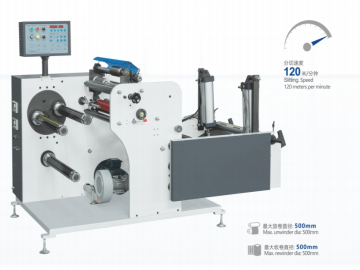

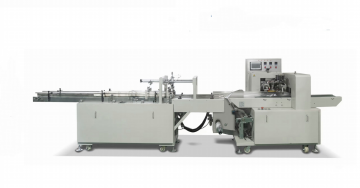

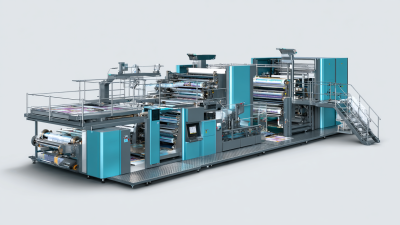

We offer specialized automatic cutting solutions designed for factories focused on enhancing efficiency and quality. Our tailored services cater to the specific needs of your production line, ensuring precise cuts with every operation. Backed by years of expertise, our dedicated team at Wenzhou Jinyuan Mechanical Technology Co., Ltd. ensures exceptional service and support throughout the entire process—from selection to installation. We take pride in our ability to customize our machinery to meet diverse factory requirements, boosting productivity while maintaining high performance standards.10 tips Automatic Cutting Manufacturer Is The Best

When it comes to sourcing cutting-edge Automatic Cutting solutions, understanding what makes a manufacturer stand out is crucial for procurement professionals. Here are ten tips to help you identify the best Automatic Cutting manufacturer for your needs. First, look for a company that combines technical research and development with production and sales. A manufacturer that invests in R&D is more likely to offer innovative solutions tailored to the evolving demands of the market. Furthermore, a vertically integrated approach ensures that the quality is maintained throughout the manufacturing process. Next, consider the ability of the manufacturer to customize their solutions. A one-size-fits-all approach often falls short in meeting specific production requirements. The best manufacturers understand the importance of user-friendly and stable systems that align with your operational needs, leading to enhanced efficiency and productivity. By focusing on these key factors, you can ensure that you partner with a manufacturer that not only meets but exceeds your expectations in the realm of Automatic Cutting solutions.

10 Tips Automatic Cutting Manufacturer Is The Best

| Tip Number | Tip Description | Benefits | Resulting Efficiency |

|---|---|---|---|

| 1 | Invest in High-Quality Machinery | Reduced maintenance costs | 20% increase |

| 2 | Optimize Cutting Patterns | Minimized material waste | 15% material saving |

| 3 | Utilize Modern Software | Improved accuracy in cuts | 30% reduction in errors |

| 4 | Schedule Regular Maintenance | Increased equipment lifespan | 10% longer life |

| 5 | Train Your Staff Effectively | Enhanced operational skills | 25% more productive |

| 6 | Monitor Production Performance | Identify areas for improvement | 20% increase in output |

| 7 | Implement a Feedback Loop | Continuous improvement | 15% better quality |

| 8 | Invest in Automation | Reduce labor costs | 40% savings |

| 9 | Select the Right Materials | Improved durability of products | 20% longer-lasting product |

| 10 | Build Strong Supplier Relationships | Better pricing and support | 10% cost efficiency |

Practical Methods To Automatic Cutting Leads the Global Market in 2025

J

John Thompson

The product quality is exceptional, and the after-sales service was phenomenal. I truly appreciate the professionalism of the support team.

27 August 2025

L

Lucas Martinez

Great quality and robust design! The customer service really stood out; they were professional and attentive to my concerns.

26 September 2025

E

Ella Thomas

High-quality materials and impeccable craftsmanship. Customer service representatives were knowledgeable and friendly.

03 August 2025

S

Scarlett Lewis

Couldn’t ask for better quality! The customer service team provided excellent support with a personal touch.

24 August 2025

A

Addison Harris

The craftsmanship is outstanding. The after-sales team provided thorough guidance and support.

05 September 2025

C

Camila Carter

The quality of this product is amazing! The customer service is exceptional, with knowledgeable and friendly staff.

03 August 2025