Contact immediately

Contact immediately Wholesale Automatic Winding Machines: Top Supplier and Factory Solutions

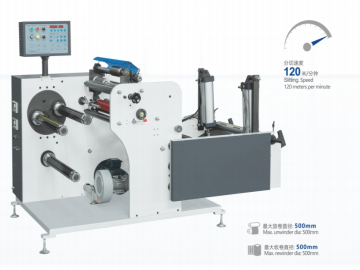

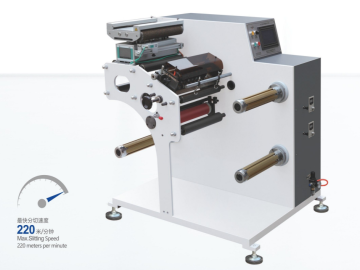

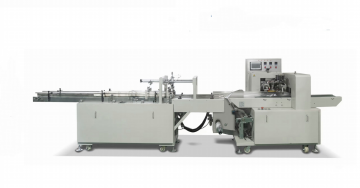

Reliable and efficient Automatic Winding Machines are essential for enhancing your production capabilities. At Wenzhou Jinyuan Mechanical Technology Co., Ltd., we offer high-quality machines at competitive prices. Our factory is dedicated to providing solutions that boost operational efficiency while keeping costs manageable. Each of our Automatic Winding Machines is designed to meet diverse specifications, ensuring durability and performance. Regardless of your business size, we cater to your specific needs with excellent customer support. Count on us as a trusted partner on your manufacturing journey with our commitment to quality and value, ensuring a strong return on your investment!

10 Essential Tips For Automatic Winding Machine Ahead of the Curve Your End-to-End Solution

When it comes to Automatic Winding Machines, staying ahead of the curve is essential for businesses looking to optimize their production lines. Here are ten crucial tips to ensure that your winding operations are efficient, reliable, and tailored to your specific needs. First, focus on the customization of the machine to align with your production requirements. A one-size-fits-all approach is often insufficient; instead, work with suppliers that understand your unique processes. Second, consider the integration of advanced technology, such as automation and real-time monitoring systems. These innovations not only enhance productivity but also provide valuable data for optimizing performance and reducing downtime. Third, ensure that your winding machines are designed with user-friendly interfaces; this simplifies training for your staff, leading to faster adaptation and fewer operational errors. Additionally, prioritize regular maintenance and support from your equipment provider. A proactive approach to maintenance can significantly extend the life of your machinery, preventing costly disruptions. Lastly, always seek feedback from your team who operates the machines daily—practical insights can lead to further improvements and innovations in your winding processes. Embracing these tips can provide a competitive edge, ensuring your operations remain agile and effective in a dynamic market.

10 Essential Tips For Automatic Winding Machine Ahead of the Curve Your End-to-End Solution

| Tip Number | Tip Description | Expected Outcome | Frequency of Implementation |

|---|---|---|---|

| 1 | Regular Maintenance Schedule | Increased machine lifespan | Monthly |

| 2 | Calibration Checks | Enhanced accuracy | Quarterly |

| 3 | Use Quality Materials | Improved product quality | Every batch |

| 4 | Operator Training Sessions | Increased efficiency | Bi-annually |

| 5 | Real-time Monitoring Systems | Immediate issue detection | Continuous |

| 6 | Data Analysis for Performance | Informed decision-making | Monthly |

| 7 | Utilize Advanced Winding Techniques | Higher production rates | As needed |

| 8 | Feedback Loop with Operators | Enhances safety and productivity | Weekly |

| 9 | Automation Integration | Reduced manual errors | During updates |

| 10 | Emergency Shutdown Protocols | Enhanced safety measures | Annual |

Key Methods For Automatic Winding Machine Products in 2025

A

Aria Davis

The quality exceeded my expectations! The customer service representatives exemplified professionalism and dedication.

11 September 2025

W

William Rodriguez

The product quality is excellent. I was particularly impressed with the professional support staff who went the extra mile.

04 September 2025

C

Charlotte White

Great product quality! The customer service team demonstrated professionalism and thorough knowledge.

15 September 2025

H

Henry Evans

The product quality is stellar! The after-sales personnel were incredibly supportive and knowledgeable.

10 September 2025

A

Abigail Sanders

Amazing quality! The expertise and professionalism of the service team made a great impact on my experience.

26 September 2025

S

Sarah Johnson

I am thrilled with this purchase. The quality is outstanding, and the after-sales service provided by the team was exceptional. They were professional and responsive.

10 August 2025