Contact immediately

Contact immediately

The die cut printer industry is rapidly evolving, driven by advancements in technology and shifting consumer demands. According to a recent market analysis, the global die cut printer market is expected to reach $3.5 billion by 2026, providing testament to the growth potential within this niche. With the rise of personalized products, die cut printers are gaining traction among businesses seeking to differentiate themselves.

Several innovations are shaping the future of die cut printers. Digital die cutting technology, for instance, enhances precision and speed. Reports show that brands utilizing these tools can improve production efficiency by up to 30%. However, despite these advancements, many companies still grapple with integrating smart systems, which can be a costly and complex process.

This landscape introduces an opportunity for reflection on the challenges within the industry. While innovation drives growth, the market also faces sustainability concerns. Many manufacturers are under pressure to adopt eco-friendly practices. As the die cut printer market flourishes, balancing innovation with environmental responsibility will be crucial for long-term success.

The die cut printing industry is on the brink of transformation as we look towards 2026. Emerging technologies are reshaping the market landscape, promising higher efficiency, speed, and versatility. According to a recent industry report, the global die cut printing market is expected to grow by 8% annually, indicating a robust demand for innovative solutions.

Automation is set to play a critical role. Smart die cutting machines are being equipped with advanced AI capabilities. These machines can self-correct errors and optimize cutting parameters in real-time. However, challenges remain. Integrating AI solutions into existing systems requires investment and training, which can be a barrier for smaller businesses. Additionally, while many companies are eager to adopt new technologies, some remain hesitant due to the learning curve involved.

Sustainability is also a driving force behind innovations. Eco-friendly materials and waste-reduction methods are becoming essential. More brands are prioritizing recyclable substrates and inks. A 2022 survey indicated that 70% of consumers prefer products that are environmentally friendly. As companies strive to meet these evolving consumer demands, they face the dilemma of balancing cost and sustainability. This tension will likely influence the trends we witness as the die cut printing landscape evolves leading into 2026.

As the printing industry evolves, eco-friendly die cutting has gained prominence. Innovations focus on reducing waste and using sustainable materials. For example, biodegradable substrates are being adopted more frequently. These materials offer a lower environmental impact. They break down naturally and reduce landfill contributions.

Another trend is energy-efficient die cutting machines. Many companies are exploring technologies that consume less power. This shift can significantly lower carbon footprints. However, initial costs may deter some businesses from making the switch. Balancing short-term expenses with long-term gains remains a challenge.

Recycling processes are also improving. Manufacturers are now using reclaimed materials in die cutting. This not only conserves resources but also redefines product life cycles. Yet, sourcing quality reclaimed materials can be inconsistent. Continuous innovation is essential to overcome these hurdles and enhance sustainability in the printing sector.

The rise of automation in die cutting processes is transforming production efficiency. Advanced technology allows for precise and quick cutting. This not only speeds up the workflow but also reduces waste. Machines are becoming smarter with real-time monitoring capabilities. They adjust settings automatically, ensuring optimal performance. However, such innovations do not come without challenges.

Many operators feel unease with machines that seem too complex. Training is essential but often lacking. Workers may struggle to adapt, which can lead to inefficiencies. Maintenance is another concern. Automated systems require regular check-ups to function correctly. The reliance on technology creates vulnerability; a machine failure can halt production.

Despite these issues, the benefits are hard to overlook. Increased speed and consistency can lead to higher profit margins. Companies are keen to adopt these changes, but they must weigh the risks. As die cutting evolves, balancing automation with skilled labor will be crucial. It’s a new era filled with exciting possibilities, yet it calls for careful consideration.

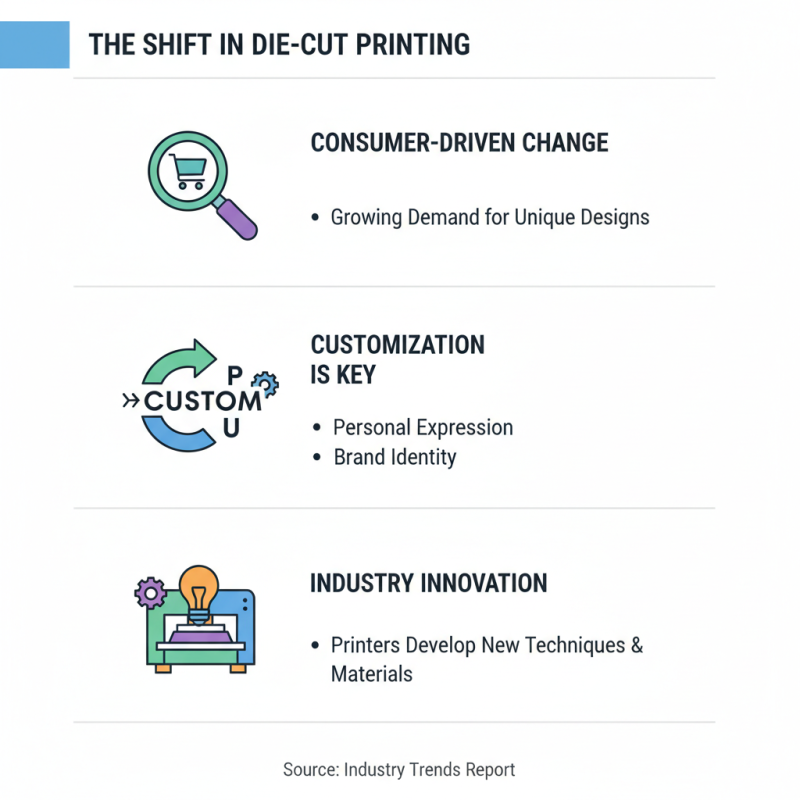

The die cut printing industry is seeing a significant shift, driven largely by consumer preferences. Customization has become a vital aspect of product offerings. People increasingly seek unique designs that reflect their personal tastes and brands. They desire items that stand out. This trend has pushed printers to innovate.

Modern consumers opt for more than just functionality; they want products that resonate with them emotionally. Vibrant colors, intricate designs, and personalized touches attract attention. However, this can lead to challenges for printers. Balancing affordability with high-quality customization is not easy. Some traditional practices may not effectively meet the new demand.

As brands explore new die-cut solutions, feedback from consumers becomes crucial. Listening to their needs can lead to better designs and outcomes. Yet, some companies may struggle to implement necessary changes. Adapting to these dynamic trends requires ongoing reflection and adjustment. The path forward remains complex but filled with potential for those willing to adapt.

As die cut technology evolves, smart technology and the IoT are shaping the future. In 2026, expect advancements that integrate connectivity with die cutting machines. Recent studies show that 70% of manufacturers are investing in smart technologies for efficiency. This shift allows for real-time data analysis and performance monitoring.

Incremental improvements are evident. Companies that adopt IoT-enabled systems report up to 30% reductions in waste. This is a game-changer. However, there are challenges. Many users struggle with integrating various technologies. Not all machines are compatible, which can slow down operations.

The role of smart technology isn't just about efficiency. It also emphasizes customization. Customers desire tailored solutions, and smart technology can deliver that. About 65% of users prefer flexible design options over traditional methods. This trend indicates a significant market shift. The path ahead is exciting yet uncertain. Embracing change and addressing integration challenges are crucial.

| Innovation/Trend | Description | Impact | Expected Adoption Rate |

|---|---|---|---|

| Smart Die Cutting Machines | Integration of IoT technology for real-time monitoring and operation. | Increased efficiency and reduced downtime. | 75% |

| Automated Workflow | Seamless integration of cutting with design and production management systems. | Streamlined operations and reduced manual errors. | 60% |

| 3D Die Cutting Technology | Enhanced design capabilities for complex shapes and dimensions. | Broader application in packaging and product design. | 50% |

| Sustainability Focus | Use of eco-friendly materials and processes in die cutting. | Improved brand image and compliance to regulations. | 68% |

| Data Analytics in Production | Utilizing data analysis for performance optimization of cutting processes. | Informed decision-making leading to cost savings. | 55% |