Contact immediately

Contact immediately

Choosing the right Automatic Winding Machine is crucial for your production needs. Many options exist, which can make the selection process overwhelming. The right machine can improve efficiency, but what makes a good choice?

Consider your specific requirements. The type of materials you will use is key. Different machines suit different purposes. Look closely at the winding speed and precision. A high-quality machine saves time and minimizes waste.

Investing time in research may feel tedious. Many machines might look similar on the surface, but their features differ significantly. Don’t hesitate to ask for recommendations or reviews. Reflect on what you truly need versus what is market hype. Each choice carries its implications. Think critically about how an Automatic Winding Machine impacts your overall operations.

When considering automatic winding machines, there are key features that directly impact performance. Pay attention to the speed of operation. A faster machine can save time, but it may compromise quality. Review the tension control system; it ensures consistent winding and prevents thread breakage. Machines with advanced sensors can greatly improve overall efficiency.

The type of motor is another important consideration. High-quality motors provide better torque and durability. Check if the machine has adjustable settings. This flexibility allows users to accommodate different materials and winding styles. Additionally, consider maintenance aspects. Some machines require frequent upkeep, which might disrupt production.

Another factor is the machine's size and footprint. Ensure that your workspace can handle the equipment dimensions. Ergonomic design enhances ease of use but is often overlooked. It’s crucial to evaluate the warranty and support available. A short warranty period may indicate potential quality issues. Overall, it's worth reflecting on these aspects to make a truly informed decision.

| Feature | Description | Importance Level |

|---|---|---|

| Winding Speed | The speed at which the machine can wind material. | High |

| Precision | Accuracy in winding to ensure quality product. | High |

| Ease of Use | User-friendly interface and controls. | Medium |

| Durability | Lifespan and ability to withstand regular use. | High |

| Versatility | Capability to handle various materials and sizes. | Medium |

| Maintenance | Ease of routine maintenance and part replacement. | High |

| Cost | Initial purchase price and ongoing operational costs. | High |

| Technology | Integration of modern technology for efficiency. | Medium |

| Customer Support | Availability and quality of customer service. | Medium |

| Safety Features | Safety measures to protect operators and materials. | High |

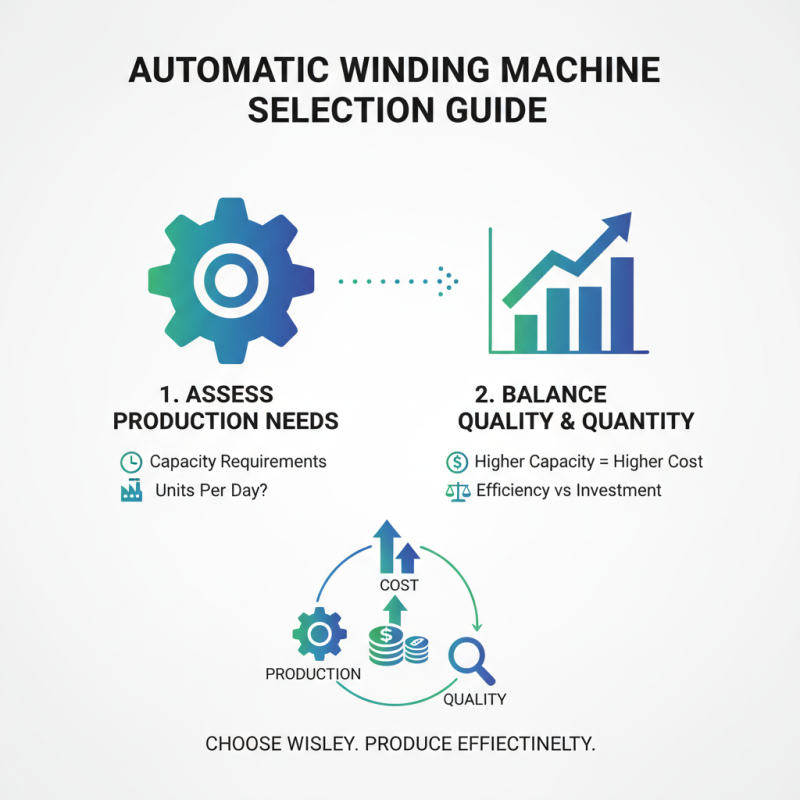

When choosing an automatic winding machine, assessing production needs is vital. Start by identifying your capacity requirements. How many units do you need to produce daily? This will guide your decision. Machines with higher capacity often come with increased costs. Ensure you balance quality and quantity.

Speed is another crucial factor. Different projects will require different speeds. Consider the type of materials you're winding. Lightweight materials might need faster speeds, while thicker ones may require more time. Reflect on your current workflow. Are you often rushing to meet deadlines? A faster machine might alleviate some pressure.

Don't overlook potential complications. Machines can have different operating modes. Familiarize yourself with these. Maintenance needs can vary by model. An automatic winding machine might promise efficiency but could introduce unexpected downtime if not maintained properly. It's important to weigh speed against reliability. Adjusting to new equipment often takes time, and this learning curve can impact output initially.

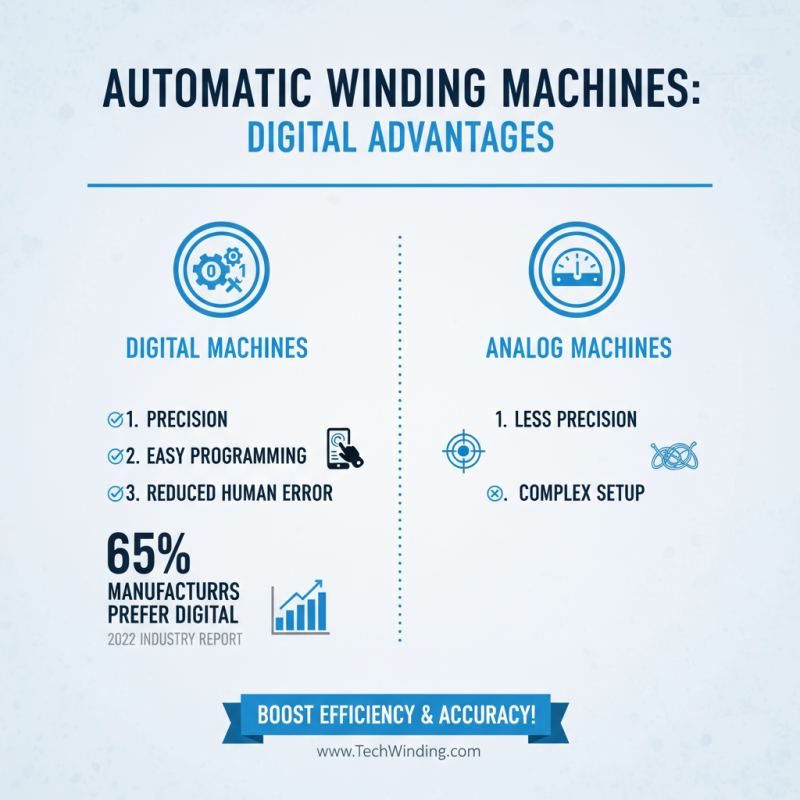

When selecting an automatic winding machine, evaluating the technology is crucial. Digital machines are gaining popularity. A 2022 industry report reveals that 65% of manufacturers prefer digital over analog. Digital machines offer precision. They simplify programming with user-friendly interfaces. This feature reduces human error, enhancing efficiency.

However, analog machines still hold ground. They are often more affordable. Some manufacturers find their simplicity appealing. The learning curve is less steep for staff. A downside is the limited flexibility. As demands shift, analog may struggle to keep up. Data shows that adaptability is vital in today's manufacturing landscape.

Tip 1: Consider your production volume. Higher volumes may benefit from digital machines. They handle complex tasks efficiently.

Tip 2: Assess your budget. Analog options can be more cost-effective, but they might lack advanced features. Ensure you weigh the long-term benefits against initial costs.

Tip 3: Evaluate maintenance needs. Digital machines may require skilled technicians for troubleshooting. Analog could be easier to fix in-house.

When selecting an automatic winding machine, consider the importance of maintenance and customer support. A manufacturer’s customer service can greatly influence your decision. If a machine breaks down, quick access to support is crucial. Delayed repairs can lead to significant production losses. Choosing a manufacturer with strong customer service can mitigate these issues.

Look for companies that offer comprehensive maintenance plans. Regular upkeep is vital for optimal performance. Machines that are well-maintained last longer and operate efficiently. Some manufacturers might provide detailed manuals, while others offer training sessions. This training can be invaluable for your team. It empowers them to troubleshoot minor issues. Yet, reliance on customer service still remains important.

Moreover, not all companies have the same response time. Some may take days to address a problem, while others respond within hours. Reflect on your past experiences with service teams. Have they met your needs? Is their communication clear? Observing these aspects may help you choose wisely. A reliable support system can make the difference between production success and failure.

This chart represents the importance rating of various factors to consider when choosing an automatic winding machine. Ratings are on a scale of 1 to 10, with 10 being the most important. Insight into these factors can help potential buyers prioritize their needs effectively.

When investing in an automatic winding machine, budgeting wisely is crucial. The initial cost can be daunting. However, it's essential to consider long-term benefits. A higher-quality machine may require a larger upfront investment, but its durability and efficiency can lead to significant savings over time.

Analyze all costs involved. This includes maintenance, energy usage, and potential repairs. An inexpensive model may save you money initially, but frequent repairs can quickly add up. Think about how much time the machine will save you. Time lost can be quite costly for your business.

When choosing a machine, consider its features. Look for options that enhance productivity without overwhelming complexity. Advanced technology can improve performance but might come with a steeper price.

Evaluate your needs thoroughly. A machine that aligns with your requirements can be a worthwhile investment. Remember, cheap does not always mean better. A balance of quality and cost should guide your decision.