Contact immediately

Contact immediately

In the world of printing, the right equipment is essential. A Printing Machine can dramatically affect the quality and speed of production. Various types of printing machines serve different needs. Some are perfect for small businesses, while others cater to large-scale operations.

Understanding the different printing machines is crucial. Each type has unique capabilities and applications. From inkjet to offset, the options can be overwhelming. Choosing the wrong machine can lead to inefficiencies. Every printer has its strengths and weaknesses, which require careful consideration.

Investing in a printing machine is not just about cost; it's about the value it brings. You should explore each type's features and limitations. Knowledge is power in this industry. The right choice can elevate your work, while the wrong one might hinder progress. This guide will delve into the top 10 types of printing machines that every business should consider.

Printing technology has evolved significantly in recent years. Each type of printing machine offers unique benefits.

Understanding these differences can help in choosing the right one for specific needs.

Offset printing is one of the most common types. It uses plates to transfer ink onto a rubber blanket, which then applies it to paper. This method is ideal for high-volume print jobs, but it requires a longer setup time.

Digital printing, on the other hand, allows for quick turnarounds. It eliminates the need for plates and prints directly from a computer. However, it may not be cost-effective for larger runs.

Flexography is popular in packaging. It uses flexible relief plates and is ideal for printing on various substrates. This method works well for long runs but may have limitations in color accuracy.

Screen printing is another technique often used for textiles. It's versatile, yet it can be cumbersome for detailed designs.

Each method has advantages and challenges. Choosing wisely requires careful consideration of project requirements and limitations.

Offset printing is a widely used technique in the printing industry, particularly for large-volume jobs. This method involves transferring ink from a plate to a rubber blanket, which then applies it to the printing surface. It's known for producing consistent quality across large runs, making it ideal for newspapers, magazines, and brochures. The precision it offers is unmatched, but it requires careful setup and calibration.

However, offset printing isn't without its challenges. The initial setup can be time-consuming and costly, especially for smaller projects. While the quality is high for large runs, the same consistency may be hard to achieve for smaller quantities. Furthermore, maintaining equipment can become complex. Regular cleanings and inspections are crucial to avoid any imperfections in the print quality. This industry continues to evolve, adapting to the digital age while still holding value in traditional print media.

Digital printing machines have transformed the printing industry in recent years. Unlike traditional printing methods, these machines produce high-quality prints with faster turnaround times. The global digital printing market will surpass $27 billion by 2025, according to industry research. This shift highlights the growing demand for quick and customizable printing solutions.

One remarkable aspect of digital printing is its versatility. These machines can handle various substrates, from paper to fabric. Additionally, they enable shorter print runs, making them ideal for small businesses and personalized products. However, there are challenges. Not all digital printers can achieve the same color accuracy. This inconsistency can lead to varied results, which may frustrate customers seeking perfection.

While digital printing offers numerous advantages, it also raises concerns about waste and environmental impact. Ink usage can be significant, and not all machines are eco-friendly. Yet, investments in sustainable technologies are rising. Many companies are striving to reduce waste and improve efficiency. As the industry evolves, finding a balance between innovation and sustainability is essential.

| Type of Printing Machine | Technology | Typical Uses | Advantages |

|---|---|---|---|

| Inkjet Printer | Drop-on-demand | Photos, Color Printing | High Quality, Affordable |

| Laser Printer | Laser Technology | Office Documents, High Speed | Fast, Cost-Effective for Text |

| Digital Press | Electrophotography | Brochures, Short Runs | Variable Data Printing, Quick Turnaround |

| Flexographic Printer | Rotary Printing | Packaging, Labels | High Speed, Wide Substrate Range |

| Offset Printer | Plate-based | Books, Newspapers | High Quality, Economical for Large Runs |

| 3D Printer | Additive Manufacturing | Prototyping, Industrial Parts | Customization, Complex Shapes |

| Sublimation Printer | Dye Transfer | Apparel, Custom Items | Vibrant Colors, Durable Prints |

| Gravure Printer | Intaglio Printing | High-quality Packaging | Rich Detail, High Output Quality |

| Screen Printer | Stencil Printing | Apparel, Ceramics | Versatile, Bold Colors |

| Photo Printer | Thermal Dye Sublimation | Photographic Prints | High Resolution, Great Color Accuracy |

Flexographic printing machines are essential in packaging. They use a flexible relief plate to transfer ink onto various materials. This process is versatile and efficient, making it popular for labels, bags, and boxes. Flexography excels in high-speed printing. It can handle long runs with consistent quality.

In packaging, these machines work well with different substrates. They print on plastic, paper, and even metal. This adaptability is a key reason for their widespread use in industries. Many companies rely on flexo for their packaging needs. Brands appreciate the vibrant colors and sharp images flexo provides.

Tips for using flexographic printing machines include regularly maintaining the plates. This ensures quality remains high. It's also wise to test inks for compatibility with substrates. Adjust your setup according to material properties. Don't underestimate the power of proper alignment; inaccuracies can lead to wasted materials. Always monitor production closely to catch issues early and avoid downtime.

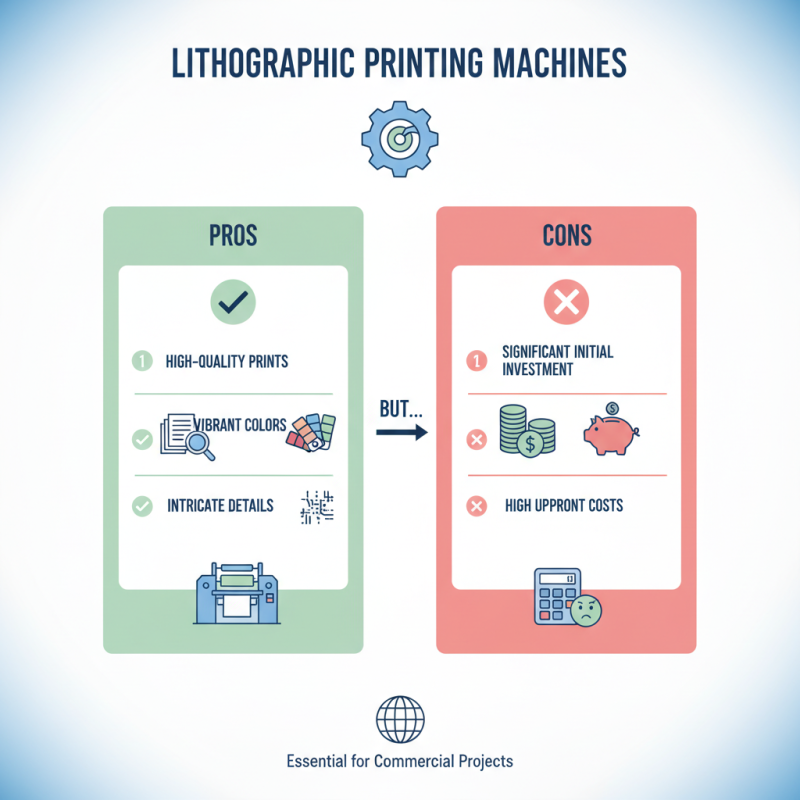

Lithographic printing machines have become an essential part of the printing industry. They excel in producing high-quality prints, making them a popular choice for commercial projects. Their ability to replicate vibrant colors and intricate details is impressive. However, these machines also come with limitations. For instance, they require a significant initial investment. Many businesses may struggle with the upfront costs.

The printing process can be time-consuming. Each print job needs specific plates, which can delay production. This might not suit fast-paced environments where quick turnarounds are vital. Maintenance of lithographic machines is another concern. They need regular check-ups to ensure optimal performance. Neglecting maintenance can lead to costly repairs and downtimes.

Moreover, it’s important to consider environmental factors. Lithographic printing generates waste, such as chemicals and paper remnants. While some companies adopt eco-friendly practices, not all do. This can raise concerns among environmentally conscious consumers. Balancing quality and sustainability remains a challenge for many.

In the evolving landscape of the printing industry, understanding the different types of printing machines is essential for businesses and enthusiasts alike. The article outlines various printing technologies, starting with offset printing machines, which are renowned for their quality and efficiency in high-volume production. Digital printing machines have emerged as a game-changer, allowing for quick turnaround and customization in smaller runs.

Flexographic printing machines are particularly effective in packaging, while lithographic printing machines offer numerous advantages despite some limitations. Lastly, screen printing machines are highlighted for their versatility in creating custom designs. Each type of printing machine has unique applications and strengths, making it crucial to choose the right one based on specific printing needs.