Contact immediately

Contact immediately Top Custom Die Cutting Equipment from Leading Manufacturers and Factories

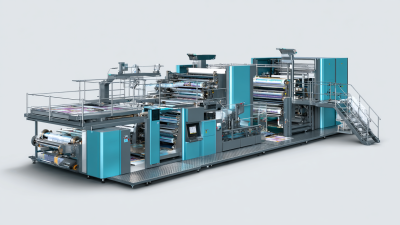

In the realm of Die Cutting Equipment, securing reliable suppliers is crucial for ensuring quality and service. With my background in the industry, Wenzhou Jinyuan Mechanical Technology Co., Ltd. has emerged as a trusted partner. Their equipment is engineered to fulfill a variety of needs, providing precision and efficiency in every cut. What distinguishes them is their unwavering dedication to customer satisfaction and comprehensive after-sales support. Choosing a supplier that not only delivers high-grade machinery but also comprehends the intricacies of the Chinese market is vital. Wenzhou Jinyuan prioritizes your business objectives and offers a range of die cutting solutions that enhance productivity while lowering operational costs. Collaborating with them, whether you’re a startup or an established entity, can drive significant growth and quality improvements in your manufacturing processes.

Quick Tips To Die Cutting Equipment Your Trusted OEM Partner Manufacturer

When it comes to Die Cutting Equipment, choosing a reliable OEM partner manufacturer is crucial for ensuring quality and productivity in your operations. As a global purchaser, you’re likely looking for solutions that not only meet your specifications but also enhance your production efficiency. A strong manufacturing partner will offer advanced equipment that seamlessly integrates into your existing workflow, minimizing downtime and maximizing output. A key consideration in your selection process should be the manufacturer's capability to provide tailored solutions. The right partner will take the time to understand your unique production challenges and customization needs. This collaborative approach ensures that you receive user-friendly, stable systems designed specifically to align with your operational objectives. Additionally, their commitment to technical R&D can lead to innovative solutions that keep you ahead of the competition in a rapidly evolving market. Lastly, effective communication and support from your OEM manufacturer are essential for a successful partnership. A responsive team that assists with installation, training, and ongoing maintenance can significantly enhance your experience and operational effectiveness. By focusing on these factors, you can confidently select a Die Cutting Equipment provider that will support your business growth and ensure long-term success in your industry.

Quick Tips To Die Cutting Equipment Your Trusted OEM Partner Manufacturer

| Feature | Description | Benefits | Recommended Equipment |

|---|---|---|---|

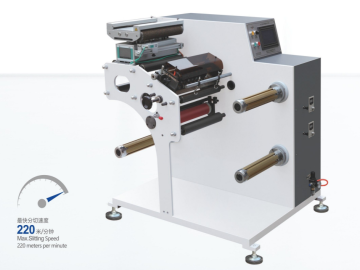

| Precision Cutting | High accuracy in cutting various materials including paper, fabric, and plastic. | Minimizes waste and enhances product quality. | Laser Die Cutters |

| Versatility | Ability to cut different materials with customizable settings. | Suitable for various applications across industries. | Rotary Die Cutters |

| Efficiency | Fast production speeds and automated processes. | Increases throughput and reduces operational costs. | Flatbed Die Cutters |

| User-Friendly Interface | Intuitive controls and software for easy operation. | Reduces learning curve for staff and enhances productivity. | Digital Die Cutters |

| Durability | Robust construction designed for long-term use. | Lower maintenance costs and fewer downtimes. | Heavy-Duty Die Cutters |

Reasons to Choose Die Cutting Equipment in 2025 Where Innovation Meets 2025

J

James Wilson

Exceptional product quality! The staff was proactive in providing assistance and ensured all my questions were thoroughly answered.

13 September 2025

S

Scarlett Lewis

Couldn’t ask for better quality! The customer service team provided excellent support with a personal touch.

24 August 2025

C

Charlotte White

Great product quality! The customer service team demonstrated professionalism and thorough knowledge.

15 September 2025

H

Henry Evans

The product quality is stellar! The after-sales personnel were incredibly supportive and knowledgeable.

10 September 2025

D

David Williams

What a fantastic experience! The product arrived in perfect condition, and the after-sales personnel were knowledgeable and courteous. Highly recommend!

17 September 2025

L

Linda Thomas

Amazing product! The quality is exceptional, and the after-sales service was provided by highly skilled personnel.

17 August 2025