Contact immediately

Contact immediately High-Quality Flexo Printing & Die Cutting Machines | Top Suppliers & Factory

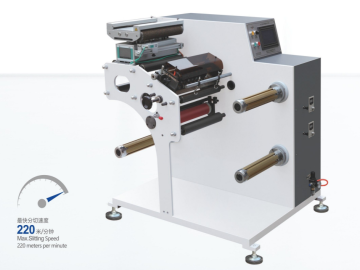

Finding a dependable Flexo Printing And Die Cutting Machine means prioritizing high-quality equipment that enhances production efficiency. Our machines are engineered to satisfy the stringent requirements of the printing industry, delivering sharp prints and precise cuts consistently. As a reliable manufacturer, we pride ourselves on our dedication to quality and innovation, leveraging advanced technology and comprehensive testing protocols to ensure our products surpass industry benchmarks. Choosing Wenzhou Jinyuan Mechanical Technology Co., Ltd. signifies an investment in durability and exceptional performance. Let's work together to elevate your production capabilities with our tailored solutions.

Best Practices For Flexo Printing And Die Cutting Machine in 2025 Supplies the World’s Top Brands

In 2025, the flexo printing and die-cutting industry is poised to undergo significant advancements that cater to the evolving demands of the global market. As brands strive for efficiency and sustainability, it’s crucial for suppliers to consider best practices that align with these trends. One of the primary focuses will be on optimizing machine performance through advanced technology integration. Implementing automation and data analytics can significantly enhance operational efficiency, reduce waste, and improve product quality. By investing in machines that support real-time monitoring and adjustment, companies can ensure consistent output that meets the rigorous standards of top brands. Another key aspect is the customization of solutions to meet specific production requirements. As brands diversify their product lines and packaging needs, versatility in flexo printing and die-cutting equipment becomes essential. Manufacturers should prioritize equipment that offers flexibility in handling various materials and thicknesses without compromising efficiency. Furthermore, fostering collaboration between equipment providers and packaging designers can lead to innovative approaches that enhance both functionality and aesthetics of the final product, ensuring that emerging brands can compete on a global scale. Lastly, sustainability remains a pivotal concern for brands and consumers alike. Suppliers should focus on developing environmentally friendly machinery that reduces energy consumption and material waste. By harnessing eco-friendly technologies and materials, manufacturers can not only decrease their carbon footprint but also appeal to an increasingly eco-conscious market. As flexo printing and die-cutting practices evolve, embracing these best practices will ultimately allow brands to thrive in a competitive landscape, ensuring they remain at the forefront of innovation while meeting the demands of their customers.

Best Practices For Flexo Printing And Die Cutting Machine in 2025 Supplies the World’s Top Brands

| Process | Best Practice | Efficiency Rating | Material Type | Common Applications |

|---|---|---|---|---|

| Flexo Printing | Use high-quality anilox rollers | 95% | Plastic, Paper | Labels, Packaging |

| Die Cutting | Optimize die maintenance schedule | 90% | Cardboard, Flexible Film | Boxes, Custom Shapes |

| Ink Selection | Choose quick-drying inks | 92% | Solvent-based, Water-based | Food Packaging, Labels |

| Quality Control | Implement inline inspection systems | 97% | Various | All Products |

| Training | Regular operator training sessions | 94% | N/A | All Equipment |

Uncovering Flexo Printing And Die Cutting Machine Dominates Global Reach

W

William Davis

The item is built to last. I was particularly impressed by how well the customer service team handled my inquiries.

08 September 2025

A

Addison Harris

The craftsmanship is outstanding. The after-sales team provided thorough guidance and support.

05 September 2025

W

William Rodriguez

The product quality is excellent. I was particularly impressed with the professional support staff who went the extra mile.

04 September 2025

V

Victoria Rivera

Fantastic quality! The after-sales service was incredibly responsive, with staff who really know their product well.

07 September 2025

S

Sarah Johnson

I am thrilled with this purchase. The quality is outstanding, and the after-sales service provided by the team was exceptional. They were professional and responsive.

10 August 2025

E

Emily Davis

I’m very pleased with the quality of the product. The after-service team demonstrated exceptional expertise and provided quick solutions to my queries.

29 September 2025