Contact immediately

Contact immediately Top Custom Flexo Printing Materials from Leading Manufacturers and Factories

At Wenzhou Jinyuan Mechanical Technology Co., Ltd., we focus on delivering high-quality Flexo Printing Materials tailored to the specific needs of various industries. Understanding that each factory has its unique requirements, we provide custom solutions designed for optimal performance and efficiency. As a trusted supplier, our materials are crafted to enhance the quality of your printing, ensuring vibrant colors and sharp details to help you stand out in a competitive market. Our commitment to excellence includes working closely with clients to offer personalized service and quick response times. We provide reliable Flexo Printing Materials that can elevate your production processes, supported by exceptional customer care to facilitate smooth and efficient printing operations. Partner with us for outstanding results together.Best Ways To Flexo Printing Materials Ahead of the Curve in 2025

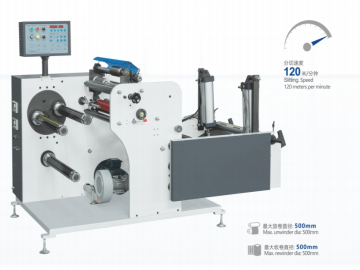

As the printing industry evolves, Flexo Printing continues to gain traction due to its versatility and efficiency. Looking ahead to 2025, it's essential for businesses to stay ahead of the curve by adopting the best practices and materials that will enhance their operations. One critical aspect to consider is the selection of high-quality substrates that can withstand the demands of modern Flexo Printing. Materials that offer excellent printability, durability, and compatibility with various inks will not only improve print quality but also reduce waste and costs. Investing in advanced slitting and rewinding equipment is another vital step for companies aiming to stay competitive. These solutions are tailored to meet the specific needs of each production line, enhancing efficiency and output. By integrating smart technology into the production process, businesses can achieve stable and user-friendly operations that respond quickly to market demands. Embracing automation and data analytics will allow for better resource management and optimization, setting the stage for successful production in a fast-evolving environment. In addition, fostering strong partnerships with suppliers and staying updated on industry trends will give businesses a competitive edge. Networking with industry leaders and participating in events can provide insights into emerging materials and innovative practices that can be incorporated into Flexo Printing operations. By prioritizing these strategies, companies can ensure they are ready to meet the challenges of 2025 while delivering optimal results to their clients.

Best Ways To Flexo Printing Materials Ahead of the Curve in 2025

| Material Type | Sustainability Rating | Print Quality (1-10) | Cost per Unit | Market Trend Indicator |

|---|---|---|---|---|

| Water-Based Inks | High | 8 | $0.05 | Growing |

| UV-Curable Inks | Moderate | 9 | $0.08 | Stable |

| Solvent-Based Inks | Low | 7 | $0.06 | Declining |

| Bio-Based Inks | Very High | 8 | $0.07 | Emerging |

| Recyclable Substrates | High | 8 | $0.10 | Increasing |

Top 5 Flexo Printing Materials Stands Out Now Trending

L

Logan Davis

Wonderful quality and a pleasure to deal with such knowledgeable staff during the after-sales process.

16 August 2025

I

Isabella Garcia

I love the quality of this item! The support representatives are highly skilled and made my experience smooth.

12 September 2025

H

Harper King

Very high-quality product! The customer service exceeded my expectations; they were friendly and highly efficient.

14 September 2025

E

Ella Nelson

Superb product quality! Their service is unparalleled; the staff made this a fantastic purchasing experience.

16 August 2025

L

Layla Perez

Loved the quality of this item! The after-sales service staff were professional and attentive, which made a real difference.

16 August 2025

M

Matthew Moore

The quality of this product is outstanding, and the after-sales support is commendable. The representatives were professional and knowledgeable.

26 September 2025