Contact immediately

Contact immediately Affordable Flexographic Presses from Trusted Manufacturers and Factories for Your Needs

Reliable Flexographic Press Solutions

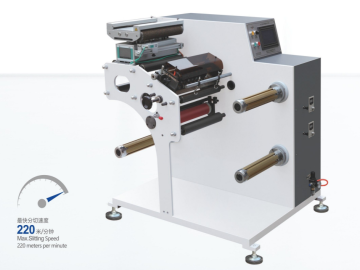

Finding a dependable Flexographic Press is essential for your printing projects. Wenzhou Jinyuan Mechanical Technology Co., Ltd. offers high-quality Flexographic Presses that maintain exceptional performance without straining your budget. Our machines deliver unmatched precision and durability, ensuring outstanding results for all your printing needs.

Key Methods For Flexographic Press Application Guarantees Peak Performance

Flexographic Printing has become an essential component in the packaging and labeling industry, known for its efficiency and versatility. Achieving peak performance from flexographic presses is crucial for businesses looking to optimize production and minimize waste. Here, we explore key methods for ensuring your flexographic press applications deliver consistent quality and high output. One fundamental aspect is the importance of selecting the right equipment tailored to specific production needs. Properly calibrated presses enhance print quality, enabling sharper images and more vibrant colors. Invest in reliable slitting and rewinding systems that can maintain tension and facilitate smooth workflows. Regular maintenance and timely upgrades are vital to address wear and tear, ensuring the press operates at optimal levels. Furthermore, training operators on best practices in handling materials and operating the presses can lead to significant improvements in performance. Understanding the intricacies of ink types, substrate compatibility, and drying processes allows for better control over the production variables. Implementing systematic quality checks throughout the production cycle can help identify potential issues early, reducing downtime and ensuring that the final product meets the highest standards. By focusing on these key methods, businesses can maximize the performance of their Flexographic Printing applications and achieve impactful results in a competitive market.

Key Methods For Flexographic Press Application Guarantees Peak Performance

| Method | Description | Benefits | Efficiency Impact |

|---|---|---|---|

| Quality Control | Implementing stringent quality assurance checks throughout the process | Ensures product consistency and reduces waste | High |

| Ink Management | Utilizing advanced ink systems to optimize performance | Improves color accuracy and reduces drying time | Moderate |

| Regular Maintenance | Scheduled servicing of machinery to prevent downtime | Ensures longevity of equipment and sustained performance | Very High |

| Training Programs | Continuous training for operators on new techniques | Enhances operator skills and productivity | High |

| Color Management Systems | Employing software to ensure color consistency | Minimizes color variance and enhances brand integrity | High |

Best Way To Choose Flexographic Press Service More Than a Supplier - A Partner

O

Olivia Martinez

The product exceeded my expectations in quality. The after-sales service team demonstrated remarkable expertise and dedication.

18 September 2025

C

Chloe Young

Outstanding purchase experience! The staff showed great product knowledge and provided support promptly.

27 September 2025

O

Oscar Hall

Great quality product! The customer service staff were knowledgeable and made the process seamless.

23 August 2025

R

Robert Davis

I’m really satisfied with my purchase. The product exceeded my expectations, and the after-sales team was very responsive.

23 September 2025

H

Harper King

Very high-quality product! The customer service exceeded my expectations; they were friendly and highly efficient.

14 September 2025

G

Gabriel Hughes

I love the quality of this product! The after-sales representatives were knowledgeable and very helpful.

05 September 2025