Contact immediately

Contact immediately

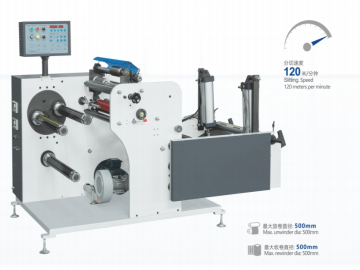

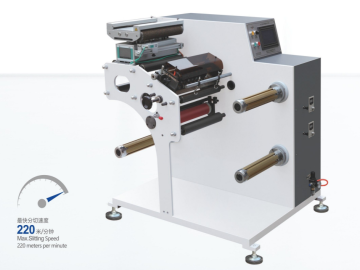

High-Performance Non-Stop Rewinding Machine

High-Efficiency Non-Stop Operation, Doubled Productivity

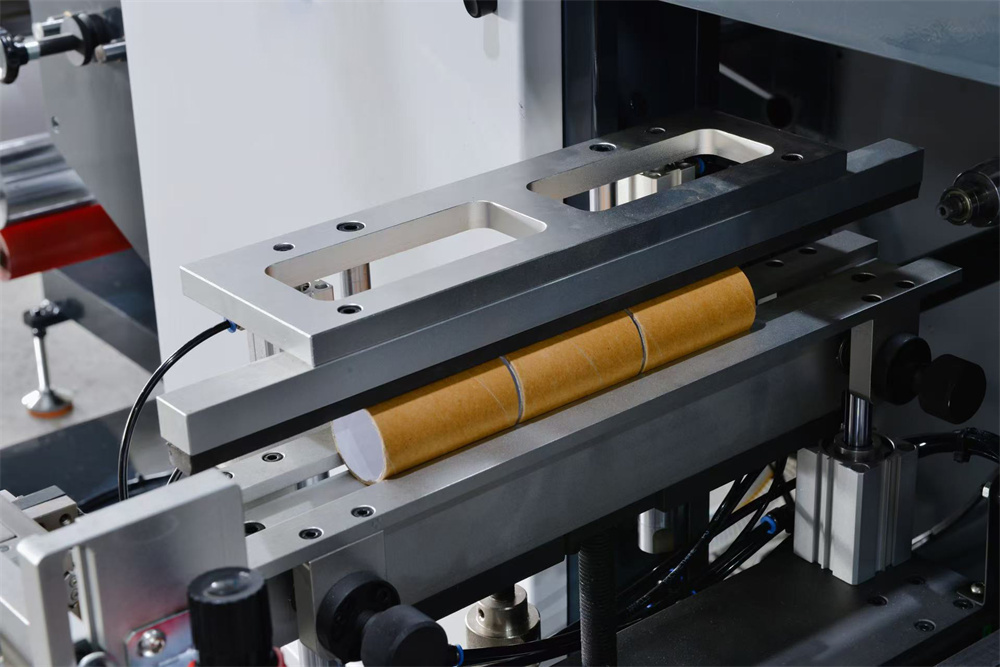

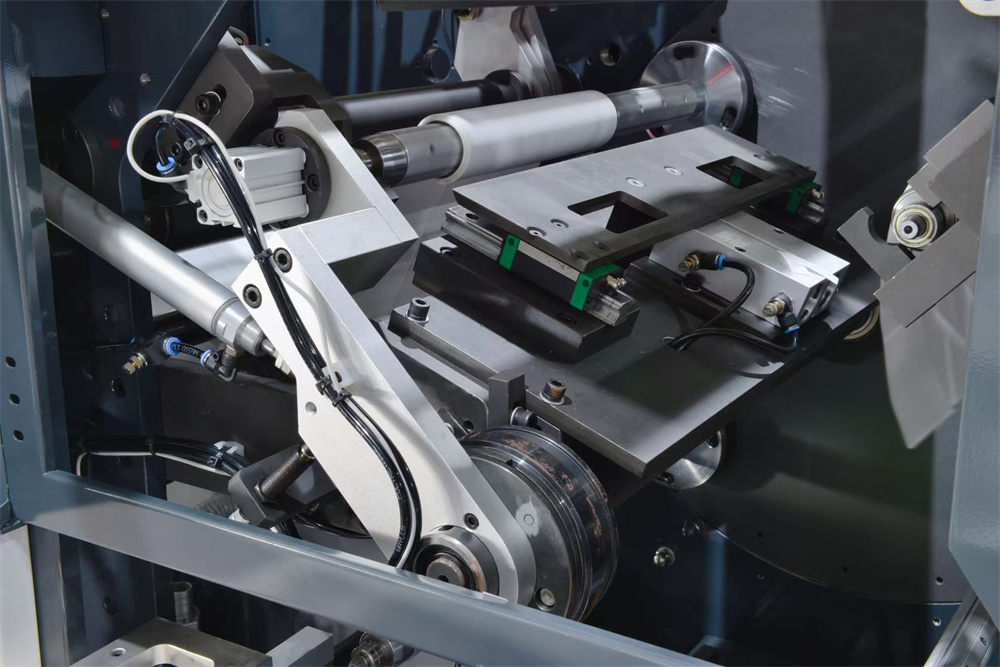

Featuring a 4-axis rewinding system, combined with automatic roll change via air expansion shafts and automatic tail cutting, it achieves a fully non-stop production mode, boosting efficiency by 2-3 times compared to traditional equipment.

Automatic material pushing and robotic arm unwinding reduce manual operations. With a slitting speed of 30-130 meters per minute, it significantly enhances mass production efficiency.

Precise Control for Stable Quality

Adopting a PLC + touchscreen intelligent control system, parameter setting is convenient, with support for automatic length counting. Slitting width error is only ±0.3mm, and rewinding alignment error is ±0.5mm, ensuring neat cuts and precise dimensions.

Full servo drive paired with a pressure roller device guarantees tight winding, preventing loose rolls and improving product consistency.

Flexible Adaptability for Wide Applications

Capable of handling materials with a width of 200-580mm (customizable) and slitting widths ranging from 25-100mm (compatible with different tools), it works with various materials such as coated paper and PET.

Widely used in industries like self-adhesive labels, electronic die-cutting, and medical packaging, especially suitable for high-volume, high-precision production needs.

Intelligent Upgrade for Easy Operation

Optional vision system available to monitor edge cutting and material defects in real-time, reducing defective products and improving yield.

Intuitive parameter setting and simple operation require no complex training, lowering labor costs.

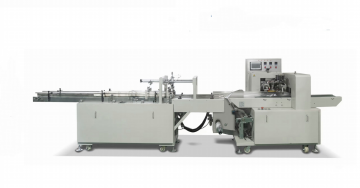

Stable, Reliable & Highly Adaptable

Designed for high performance and quality, the machine adopts advanced PLC control, boasting high speed, precision, reliability, and ease of operation, ensuring stable and industry-leading performance.

Independently developed by our company, it strictly complies with relevant safety standards, featuring an elegant design and scientifically rational internal layout. It effectively reduces labor input, enhances efficiency, and guarantees product quality—an indispensable production assistant.

Key components use high-quality materials for superior performance, ensuring long-term stable operation. With years of factory application experience, mature and reliable technology, safe operation, user-friendly design, and competitive pricing, it is widely used across multiple fields and well-recognized by customers.

Product Parameters

|

4-Axis Non-Stop Rewinder Parameter Table |

|||

| Technical Parameters | Specifications | Control System | Brands |

| Maximum Paper Passing Width | 580mm | PLC Controller | Inovance |

| Maximum Unwinding Diameter | 260mm | Servo Motor | Inovance |

| Maximum Running Speed | 130m/min | HMI (Human-Machine Interface) | Inovance |

| Equipment Installed Power | 11KW | Precision Pressure Regulator | SMC (Japan) |

| Equipment Startup Power | 4KW | Bearings | NSK (Japan) |

| Total Equipment Weight | 2.8T | Planetary Reducer | Nidec (Japan) |

| Operating Personnel | 1 person | Cylinders | Airtac |

| Usable Width Range | 200-580mm | Solenoid Valves | Airtac |

| Slitting Width Adjustment | 25-100mm | Displacement Sensors | Domestic |

| Slitting Width Error | ±0.3mm | Indicator Lights | Domestic |

| Winding Alignment Error | ±0.5mm | Stepper Motors | Domestic |

| Switching Power Supply | Rockwell | ||

| AC Contactor | Rockwell | ||

| Buttons | Rockwell | ||

| Reflective Photoelectric Sensor | Panasonic (Japan) | ||

| Relays | Rockwell | ||

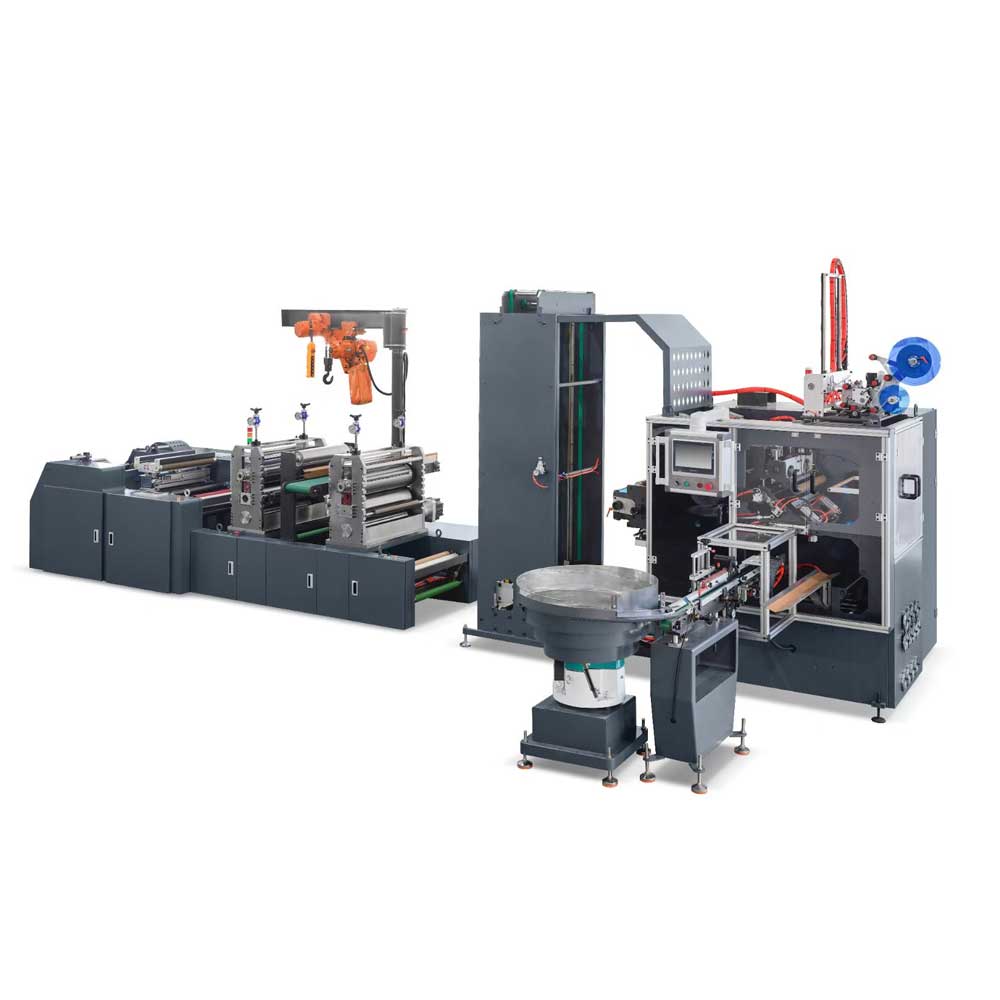

Product Display

Get in touch

We're Ready To Assist You Anytime