Contact immediately

Contact immediately

Intelligent CNC Paper Tube Cutter

Intelligent Sensing for Precise Cutting

Automatic thickness sensing: Intelligently identifies paper tube thickness without manual intervention, greatly enhancing work efficiency and ensuring smooth production. The equipment uses advanced sensing technology to monitor and accurately determine thickness in real time, then automatically adjusts cutting parameters for precise, reliable results.

Automatic cutting depth adjustment: Intelligently matches cutting parameters and precisely controls depth, effectively preventing blade and spindle damage caused by improper operation. The built-in intelligent control system adjusts depth based on material properties and thickness, improving cutting quality while extending equipment lifespan and reducing maintenance costs.

Automatic cutting time calculation: Optimizes cutting duration based on material and thickness, ensuring consistent precision, higher productivity, and superior cutting quality.

Fully Automatic Production for Effortless Operation

Automatic height adjustment of conveyor wheels: Prevents paper tube deformation or equipment damage caused by excessive pressure.

Automatic tube-feeding lifting platform: Enables quick switching between different-sized cores, significantly improving changeover efficiency.

Automatic lubrication system: Timely lubricates key components automatically, avoiding equipment wear due to neglected maintenance.

Intelligent Optimization for Efficiency & Energy Savings

Automatic sorting of scrap ends: Eliminates manual sorting, seamlessly connecting to subsequent production processes.

Automatic cuttable quantity calculation: Input parent tube length and finished product length, and the system automatically generates the optimal cutting plan.

Multi-length combined cutting: Supports flexible cutting combinations to maximize material utilization and minimize waste.

Easy Operation & Simple Maintenance

Convenient storage of common specifications: One-click saving of frequently used cutting parameters for easy retrieval, saving time and effort.

Intuitive fault prompts: Clear photos display fault conditions, helping quickly locate and resolve issues.

User-friendly and easy to learn: Humanized interface design requires no professional training, allowing quick mastery of operations to boost work efficiency.

High Precision & Reliability

Smooth, burr-free ends: High cutting precision significantly improves overall product quality.

Mitsubishi CNC system: Mature, reliable technology ensures stable operation. The entire machine comes with a 1-year warranty, and core components are covered for 5 years.

Product Parameters

|

3103 CNC Paper Tube Cutter Parameter Table |

|||

| Technical Parameters | Specifications | Control System | Brands/Models |

| Tube Cutting Length | 1m, 1.3m, 1.6m, 1.8m, 2m, 2.5m, 3.2m | PLC Controller | Imported Mitsubishi System |

| Tube Cutting Diameter | 25-200mm | HMI (Human-Machine Interface) | Weintek |

| Number of Cutting Blades | 1 set | Program Version | 2025 |

| Cutting Table Moving Speed | 35 m/min | Frequency Converter | |

| Cutting Method | Paper tube rotates, cutter shaft remains static |

Executive Devices | Chint Products |

| Loading/Unloading Method | Automatic loading and unloading | Signal Components | Chint Products |

| Clamping Method | Automatic pneumatic chuck | Pneumatic Components | Chint Products |

| Operating Personnel | 1 person | Servo Motor | HONGBAODA |

| Feeding Method | Pneumatic cutter | Moving Screw | Jingheng |

| Minimum Slitting Width | 1mm | Moving Rail | Jingheng |

| Input Power | 380V three-phase four-wire | Cutter Material | Tungsten Steel |

| Cutting Thickness | 1mm-18mm | Included Accessories | |

| 1.3M Specification Dimensions | 3500mm*1600mm*1300mm | Cutting Blades | 2 pieces |

| 1.3M Total Weight | 1000KG | Application Tools | 1 set |

| 1.3M Total Power | 3.5KW | ||

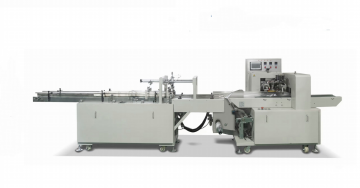

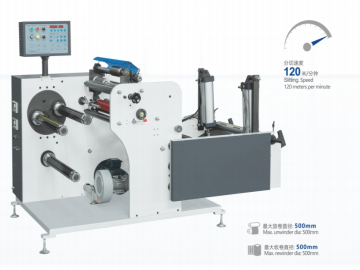

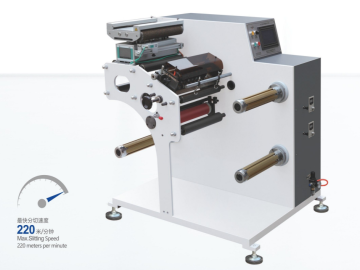

Product Display

our factory

Get in touch

We're Ready To Assist You Anytime