Contact immediately

Contact immediately

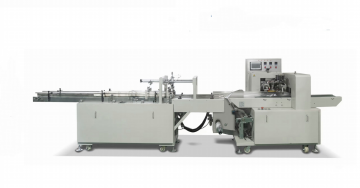

Intelligent Full-Automatic Label Production Line

Core Innovations

Industry-leading 4-in-1 automatic production line: Integrated design of paper splicer + printing station + die-cutting station + rewinder eliminates intermediate processes. Enables continuous operation, reduces manual intervention and material waste, and adapts to mass production and multi-variety switching needs.

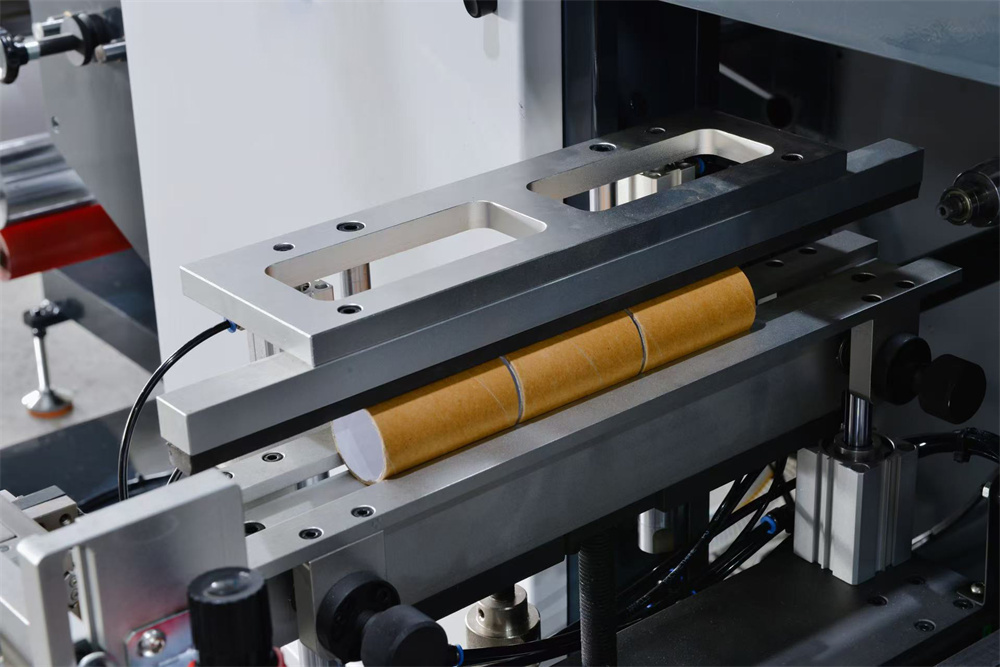

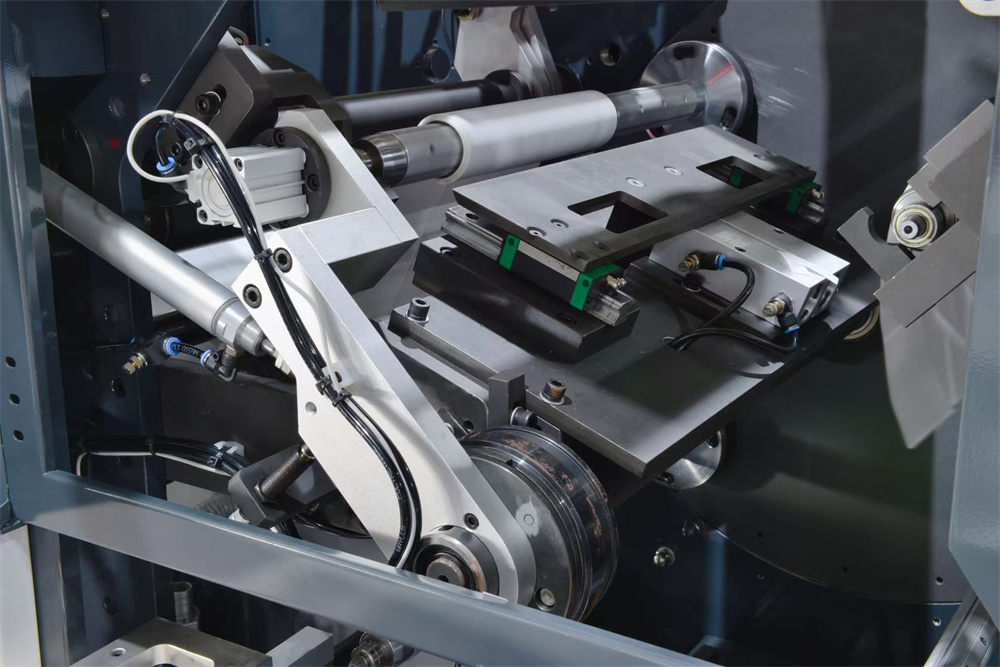

Horizontal die-cutting station with quick roller replacement boosts waste handling efficiency by 50%.

Efficiency & Precision

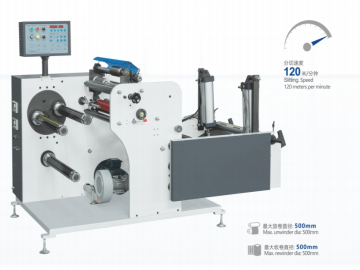

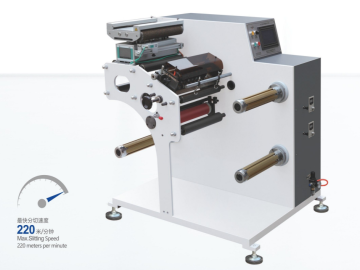

4-axis non-stop rewinder with a speed of 80-130 meters/minute; maximum finished roll diameter reaches 450mm for fast production.

Intelligent correction system ensures slitting precision of ±0.3mm and rewinding alignment of ±0.5mm, guaranteeing high product consistency.

Dual die-cutting station design: handles two specifications simultaneously or enables composite die-cutting (contour + functional lines) for enhanced production flexibility.

Intelligent Control System

Industrial touchscreen displays real-time production data and equipment status, enabling visual operation to reduce errors.

Recipe storage function allows one-click switching of product parameters for efficient changeover between different products.

Remote diagnostic system: engineers can resolve over 80% of faults online, ensuring uninterrupted machine operation.

Key Functional Modules

Independent unwinding unit: supports non-stop roll change and simultaneous processing of multiple materials.

Dual die-cutting system: Mode 1 produces two label types simultaneously; Mode 2 performs composite die-cutting (contour + functional lines) to meet diverse production needs.

Intelligent waste discharge system: automatically removes complex-shaped waste with a 99% collection rate, reducing worker workload.

Material storage buffer device: absorbs speed differences to maintain stable tension and minimize downtime losses.

After-Sales Support

1-year warranty for the entire machine: free repair and replacement of parts for faults caused by equipment quality issues during the period.

Lifetime after-sales service includes free technical consultation—professionals will patiently answer all questions customers may encounter during equipment operation. For faults in the non-stop rewinder, remote diagnostic services are provided to quickly locate issues through data analysis and propose solutions.

Product Parameters

|

4-Axis Non-Stop Rewinder Parameter Table |

|||

| Technical Parameters | Specifications | Control System | Brands |

| Maximum Paper Passing Width | 580mm | PLC Controller | Inovance |

| Maximum Unwinding Diameter | 260mm | Servo Motor | Inovance |

| Maximum Running Speed | 130m/min | HMI (Human-Machine Interface) | Inovance |

| Equipment Installed Power | 11KW | Precision Pressure Regulator | SMC (Japan) |

| Equipment Startup Power | 4KW | Bearings | NSK (Japan) |

| Total Equipment Weight | 2.8T | Planetary Reducer | Nidec (Japan) |

| Operating Personnel | 1 person | Cylinders | Airtac |

| Usable Width Range | 200-580mm | Solenoid Valves | Airtac |

| Slitting Width Adjustment | 25-100mm | Displacement Sensors | Domestic |

| Slitting Width Error | ±0.3mm | Indicator Lights | Domestic |

| Winding Alignment Error | ±0.5mm | Stepper Motors | Domestic |

| Switching Power Supply | Rockwell | ||

| AC Contactor | Rockwell | ||

| Buttons | Rockwell | ||

| Reflective Photoelectric Sensor | Panasonic (Japan) | ||

| Relays | Rockwell | ||

Product Display

Get in touch

We're Ready To Assist You Anytime