Contact immediately

Contact immediately

Intelligent Paper Tube Slitting Machine

Intelligent Programmable Cutting System

Freely programmable cutting: Users can directly input arbitrary cutting sizes and quantities via the touchscreen. The system simultaneously monitors the rationality of input parameters, effectively avoiding incorrect operations.

Multi-segment cutting program: Supports setting cutting modes with combinations of different lengths (e.g., 100mm + 200mm + 150mm).

Intelligent memory function: Features scheme encryption to ensure the security of customers' exclusive cutting processes. Users can save frequently used cutting parameters and combination schemes in the system for instant retrieval, eliminating the need for repeated input and significantly improving work efficiency.

High-Precision Cutting Technology

Servo closed-loop technology: Adopts an advanced servo drive system with real-time position feedback, ensuring cutting precision remains within ±0.1mm.

Dynamic compensation system: Automatically corrects material errors to guarantee consistency in every segment of cutting. Additionally, the system is equipped with automatic abnormal vibration detection; upon detecting vibrations, it immediately pauses the cutting process and alerts operators for adjustments.

Intelligent feeding algorithm: Automatically optimizes cutting speed and force based on material hardness, matching the optimal cutting parameters. This intelligent algorithm adjusts parameters according to different material properties to achieve superior cutting results.

Efficient & User-Friendly Human-Machine Interaction

Industrial touchscreen: Real-time display of cutting dynamic diagrams, including current cutting position, remaining stroke, and operating status.

Visual programming interface: Graphically presents cutting schemes for intuitive and easy operation.

Real-time monitoring system: Tracks cutting progress and remaining quantities in real time. When material is insufficient, the system issues a low-material warning.

Efficient Production Solutions

Automatic counting function: Accurately records the number of cut pieces and remaining cuttable quantities, automatically deducting the length of scrap ends (heads and tails) to ensure precise calculation of effective cutting quantities.

Quick die change system: Enables tool replacement in a short time to adapt to various material requirements, with no manual calibration needed after replacement.

Continuous operation mode: Equipped with an automatic material rack docking system, supporting 24/7 uninterrupted production and significantly increasing productivity.

Product Parameters

|

3103 CNC Paper Tube Cutter Parameter Table |

|||

| Technical Parameters | Specifications | Control System | Brands/Models |

| Tube Cutting Length | 1m, 1.3m, 1.6m, 1.8m, 2m, 2.5m, 3.2m | PLC Controller | Imported Mitsubishi System |

| Tube Cutting Diameter | 25-200mm | HMI (Human-Machine Interface) | Weintek |

| Number of Cutting Blades | 1 set | Program Version | 2025 |

| Cutting Table Moving Speed | 35 m/min | Frequency Converter | |

| Cutting Method | Paper tube rotates, cutter shaft remains static |

Executive Devices | Chint Products |

| Loading/Unloading Method | Automatic loading and unloading | Signal Components | Chint Products |

| Clamping Method | Automatic pneumatic chuck | Pneumatic Components | Chint Products |

| Operating Personnel | 1 person | Servo Motor | HONGBAODA |

| Feeding Method | Pneumatic cutter | Moving Screw | Jingheng |

| Minimum Slitting Width | 1mm | Moving Rail | Jingheng |

| Input Power | 380V three-phase four-wire | Cutter Material | Tungsten Steel |

| Cutting Thickness | 1mm-18mm | Included Accessories | |

| 1.3M Specification Dimensions | 3500mm*1600mm*1300mm | Cutting Blades | 2 pieces |

| 1.3M Total Weight | 1000KG | Application Tools | 1 set |

| 1.3M Total Power | 3.5KW | ||

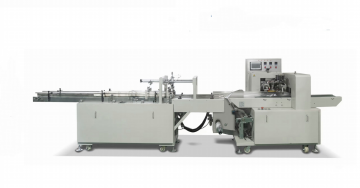

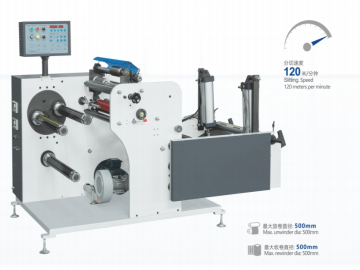

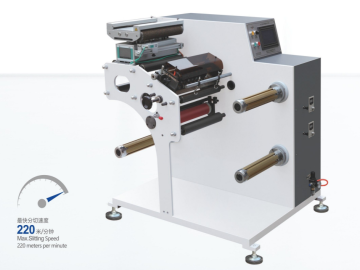

Product Display

our factory

Get in touch

We're Ready To Assist You Anytime