Contact immediately

Contact immediately

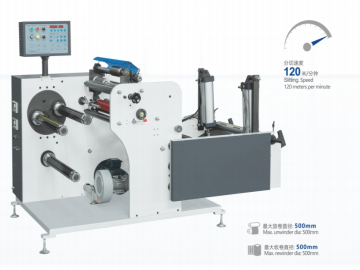

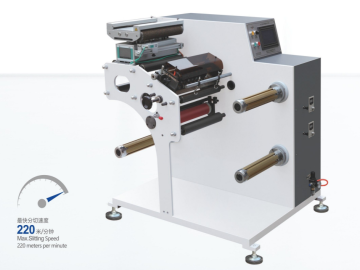

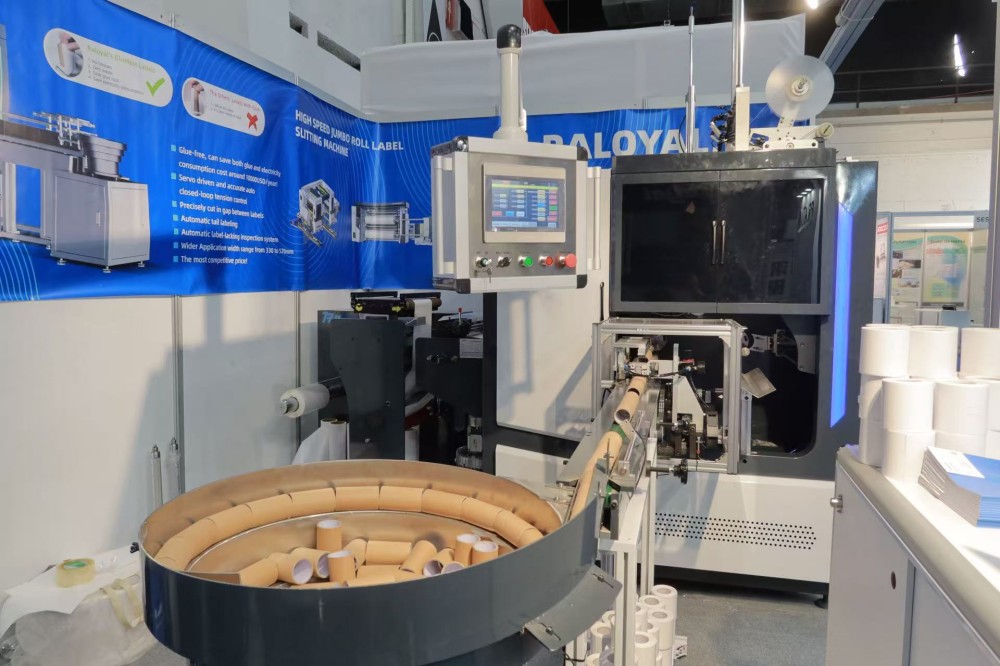

Multifunctional High-Efficiency Rewinder

Advantages in Boosted Production Efficiency

Independent unwinding efficiency: Enables non-stop roll change, drastically reducing production downtime and significantly increasing output per hour. It can handle multiple materials or rolls of different specifications simultaneously, enhancing equipment utilization.

Dual die-cutting station efficiency: In high-efficiency production mode, it can die-cut two different label specifications at the same time, maximizing equipment capacity—ideal for large-volume, multi-variety orders.

Winding system efficiency: Adopts a multi-station winding design with four-axis automatic switching, eliminating the need to stop for winding completion and maintaining a continuous production rhythm.

Advantages in Ensured Processing Precision

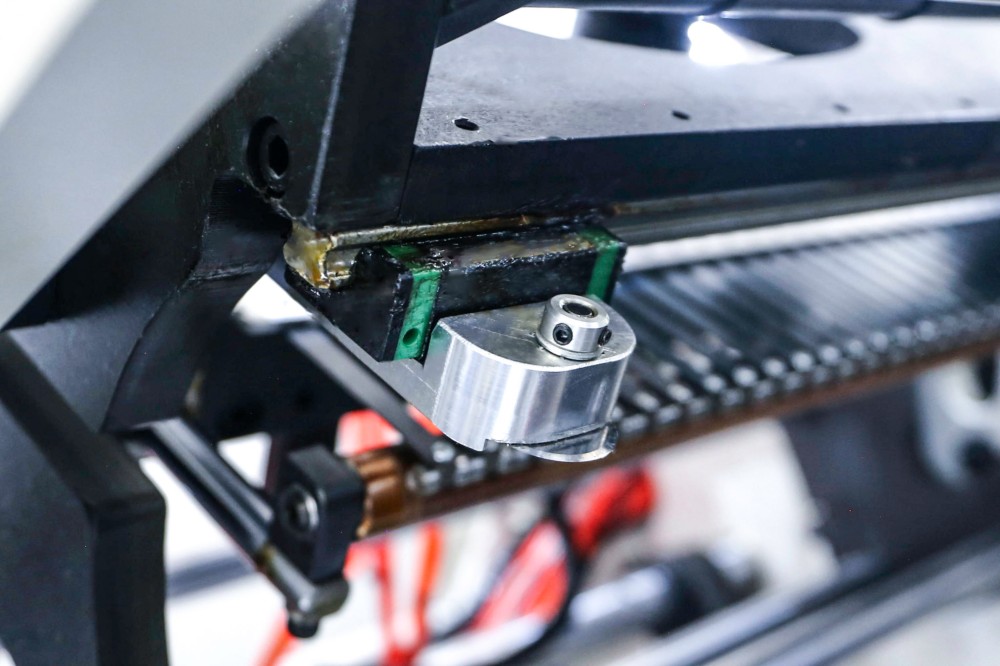

Trimmer precision: Precisely cuts off edge waste from rolls, ensuring the width accuracy of finished rolls and improving product consistency. It removes irregular edges, providing a stable foundation for subsequent processes like die-cutting and waste discharge.

Pressure gauge precision: Real-time monitors pressure at die-cutting and lamination positions, ensuring uniform die-cutting depth. This prevents cutting through the base paper or incomplete cutting, thus guaranteeing processing precision.

Precision control parameters: The slitting width error is only ±0.3mm, and the winding alignment error is ±0.5mm—far exceeding the average precision level of the industry.

Advantages in Enhanced Production Flexibility

Independent unwinding flexibility: Can handle multiple materials or rolls of different specifications simultaneously, easily coping with diverse production orders without frequent equipment adjustments.

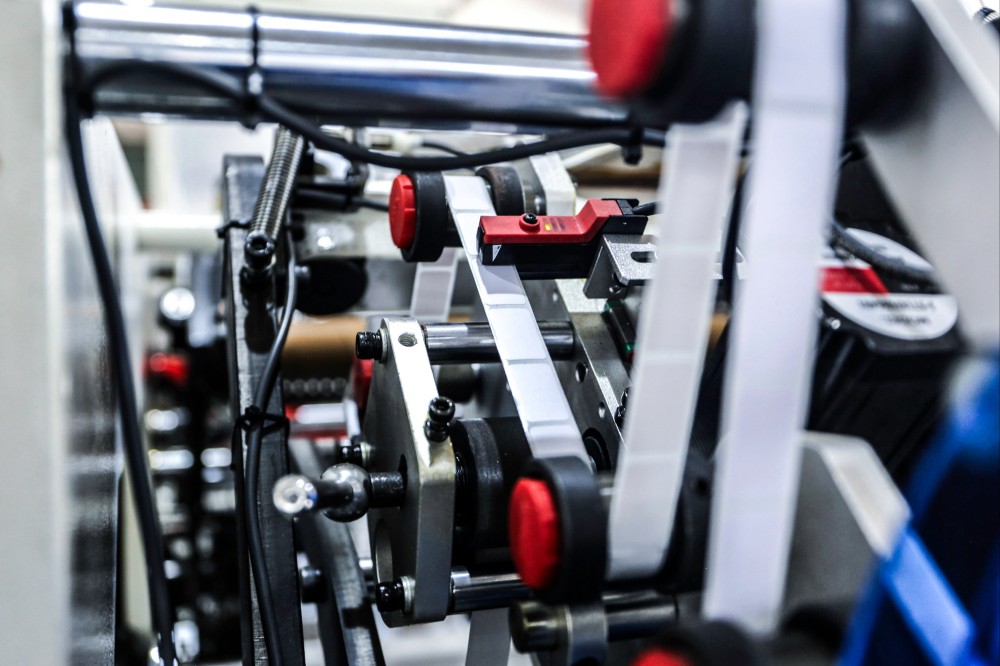

Dual die-cutting station flexibility: Two production modes can be flexibly switched according to order requirements. It can not only efficiently produce regular labels but also process high-value-added complex labels. This reduces the number of die changes, improves the ability to quickly respond to complex orders, and enhances the flexibility of production arrangements.

Material adaptation flexibility: The applicable material width is usually 200-580mm, which can adapt to the processing of rolls with various widths. The slitting width ranges from 25-100mm, which can be adjusted according to tool configuration to meet the processing needs of products with different specifications.

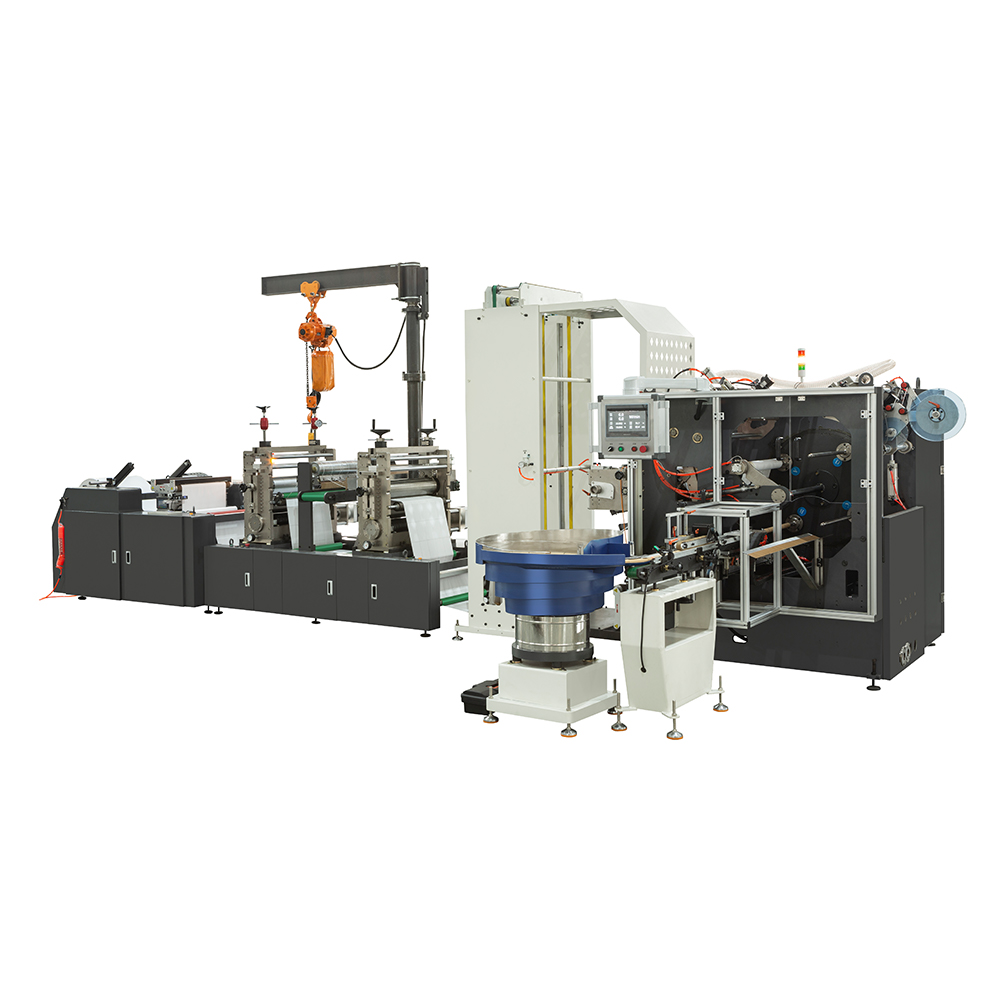

Advantages in Automation and Continuity

Vibratory bowl & automatic feeding/labeling automation: Realizes automatic sorting, conveying of small parts, and online integrated assembly with labels. This eliminates subsequent manual pasting processes, improves automation levels, reduces labor costs, and avoids errors caused by manual operations to enhance production consistency.

Waste removal automation: Automatically removes waste after die-cutting without manual cleaning, ensuring continuous production and preventing downtime caused by waste accumulation.

Rewinding system automation: The center winding is driven by a servo motor, making the winding process stable and reliable. It is equipped with air expansion shafts to realize automatic roll change and tail cutting, reducing manual involvement and ensuring the continuity and automation of the rewinding process.

Product Parameters

|

4-Axis Non-Stop Rewinder Parameter Table |

|||

| Technical Parameters | Specifications | Control System | Brands |

| Maximum Paper Passing Width | 580mm | PLC Controller | Inovance |

| Maximum Unwinding Diameter | 260mm | Servo Motor | Inovance |

| Maximum Running Speed | 130m/min | HMI (Human-Machine Interface) | Inovance |

| Equipment Installed Power | 11KW | Precision Pressure Regulator | SMC (Japan) |

| Equipment Startup Power | 4KW | Bearings | NSK (Japan) |

| Total Equipment Weight | 2.8T | Planetary Reducer | Nidec (Japan) |

| Operating Personnel | 1 person | Cylinders | Airtac |

| Usable Width Range | 200-580mm | Solenoid Valves | Airtac |

| Slitting Width Adjustment | 25-100mm | Displacement Sensors | Domestic |

| Slitting Width Error | ±0.3mm | Indicator Lights | Domestic |

| Winding Alignment Error | ±0.5mm | Stepper Motors | Domestic |

| Switching Power Supply | Rockwell | ||

| AC Contactor | Rockwell | ||

| Buttons | Rockwell | ||

| Reflective Photoelectric Sensor | Panasonic (Japan) | ||

| Relays | Rockwell | ||

Product Display

Get in touch

We're Ready To Assist You Anytime