Contact immediately

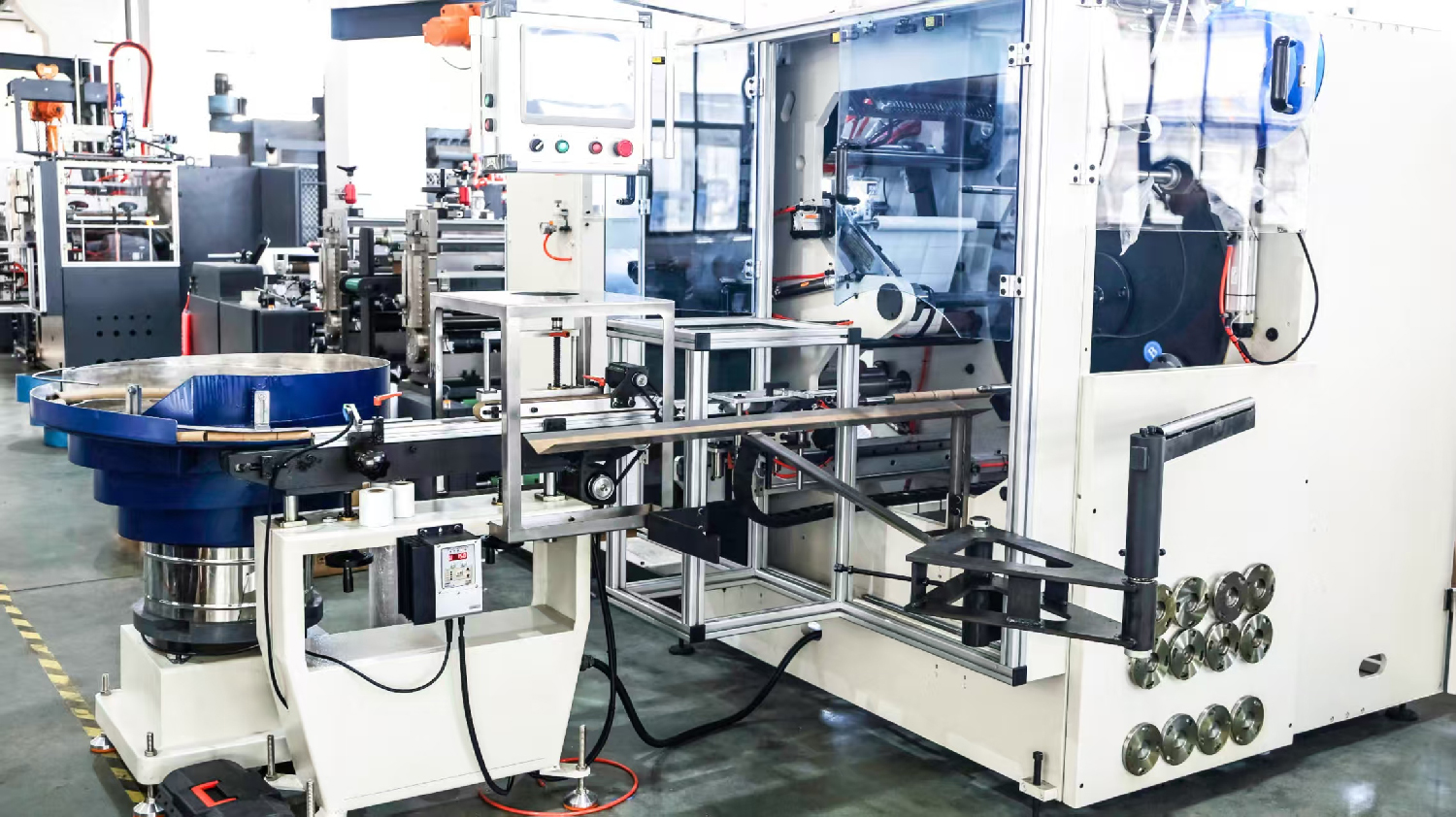

Contact immediately Introduction of our fully automatic adhesive label slitting and rewinding machine

Professional, Efficient, Intelligent Control and PrecisionIn the field of label production, efficiency and accuracy are key. Our company has launched a new generation of fully automatic adhesive label Slitting And Rewinding Machines, integrating intelligent control, efficient production, and stable operation to help enterprises reduce costs and increase efficiency.Core advantages:

1.Fully automated operation: It uses a servo motor to drive the center rewinding, equipped with an air-expanding shaft for automatic roll changing and tail cutting functions, combined with a four-axis multi-station rewinding system, achieving uninterrupted production with efficiency up to 2-3 times that of traditional equipment.

2.Precise control: It sets slitting parameters intelligently through PLC + touch screen, supports automatic meter counting and edge alignment control, with a slitting width error of only ±0.2mm and a rewinding error of ±0.5mm, ensuring that each roll of label is cut neatly and accurately in size.

3. Flexible adaptation:It can handle materials with widths of 200-600mm (customizable), with slitting speeds of 30-150m/min, supporting adjustments of slitting widths from 25-100mm, to meet the high-efficiency slitting needs of different materials (such as art paper, PET, matt silver, etc.).4. Intelligent detection (optional): It integrates a vision system to monitor the cutting edges and material defects in real-time, effectively improving the yield rate.Applicable scenarios:Widely used in industries such as adhesive labels, electronic die-cutting, and pharmaceutical packaging, especially suitable for high-volume, high-precision label slitting and rewinding needs.Choose our fully automatic Slitting And Rewinding Machine for smarter and more efficient production! Customized configurations are available, welcome to inquire for details!

Upon order confirmation and before delivery, we will update you with the progress of the machine from time to time. We will take pictures and videos and share them with you for confirmation once the goods are ready.