Contact immediately

Contact immediately Affordable Packaging and Printing Machines from Leading Manufacturers and Factories

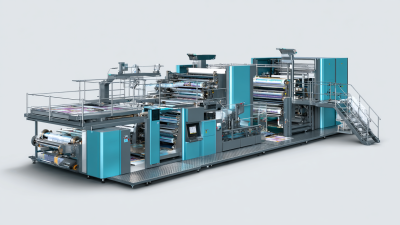

Are high-quality packaging and printing machines essential for your operations? Wenzhou Jinyuan Mechanical Technology Co., Ltd. specializes in providing custom solutions to meet diverse industry needs. Our machines are engineered for maximum efficiency and optimal performance, ensuring they fulfill your production demands. With a commitment to exceptional service, we support you at every step — from selecting the ideal machine to providing after-sales assistance, ensuring a seamless experience throughout.How-To Guide Packaging And Printing Machine From Concept to Delivery Dominates

In today's fast-paced manufacturing landscape, the efficiency and reliability of Packaging And Printing Machinery are crucial for businesses aiming to stay competitive. Crafting the ideal machine involves a comprehensive process, from initial concept development to final delivery. This guide outlines the key steps that ensure your machinery not only meets but exceeds expectations. The journey begins with understanding specific production needs. Tailoring solutions to fit actual requirements can significantly enhance operational efficiency. Collaborating with experts in technical research and development allows for insights into the latest technologies and trends, ensuring you are investing in state-of-the-art machinery. Once the concept is solidified, the focus shifts to production and manufacturing, where precision and quality control become paramount. A robust quality assurance process guarantees that every machine not only functions optimally but remains user-friendly and stable under various operational conditions. Lastly, effective delivery encompasses not just logistics but also support and training. Ensuring that the machinery is installed correctly and that the personnel are well-trained leads to minimized downtime and maximized productivity. A commitment to ongoing support fosters a lasting partnership, enabling businesses to adapt to changing demands. By following these steps, you can ensure that your Packaging And Printing Machinery stands at the forefront of the industry, helping you streamline operations and drive growth.

How-To Guide Packaging And Printing Machine From Concept to Delivery Dominates

| Stage | Description | Key Considerations | Timeline | Expected Outcome |

|---|---|---|---|---|

| Concept Development | Identifying market needs and conceptualizing machine design. | Market research, targeting audience, defining specifications. | 1 month | Clear concept outline ready for design. |

| Design Phase | Creating detailed designs and specifications for the machine. | Collaboration with engineers and designers, CAD modeling. | 2 months | Finalized machine designs ready for prototypes. |

| Prototyping | Building a functional prototype to test design and functionality. | Testing materials, feasibility studies, adjustments needed. | 3 months | Validating design and performance through testing. |

| Production | Mass production of the machines based on finalized designs. | Quality control, supplier management, logistics planning. | 4-6 months | Ready-to-market machines with high quality assurance. |

| Delivery | Shipping products to customers and providing installation support. | Effective logistics, customer communication, after-sales support. | 1 month | Successful installation and operational machines in clients’ facilities. |

Effective Ways To Packaging And Printing Machine Pioneers in the Field Trusted by Pros

D

David Lee

The craftsmanship of this product is outstanding. The after-sales personnel were knowledgeable and very helpful throughout the process.

30 August 2025

C

Chloe Young

Outstanding purchase experience! The staff showed great product knowledge and provided support promptly.

27 September 2025

M

Matthew King

Impressed with the quality! The technical support team was quick to assist and extremely knowledgeable.

06 August 2025

J

Jack Garcia

Very impressive quality! The after-sales support team was well-informed and very helpful throughout.

01 September 2025

E

Emily Johnson

I am thoroughly impressed with the product quality. The support team provided exceptional service and were very knowledgeable.

19 August 2025

I

Isaac Cooper

Superb quality and great value! The support team was friendly, knowledgeable, and very quick to respond.

12 August 2025