Contact immediately

Contact immediately Wholesale Flexo Printing Machines - Top Manufacturer & Factory Supplier

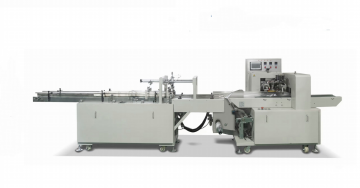

As a premier supplier of Paper Flexo Printing Machines, we offer tailored solutions to meet your unique production needs. Our machines utilize cutting-edge technology to ensure high-quality printing, helping your products capture attention in the competitive marketplace. At Wenzhou Jinyuan Mechanical Technology Co., Ltd., we prioritize reliability and efficiency, with durable machines suitable for a variety of applications, enhancing your printing capabilities for continued success.10 Essential Tips For Paper Flexo Printing Machine Guarantees Peak Performance Is The Best

Achieving peak performance in paper flexo Printing Machines is crucial for businesses seeking efficiency and cost-effectiveness. A well-maintained and optimized machine can significantly enhance production quality and speed. Here are ten essential tips for ensuring that your paper flexo Printing Machine operates at its best. First, regular maintenance is key. Develop a structured maintenance schedule to inspect and clean components, ensuring that all parts, especially the anilox rollers and doctor blades, are in good condition. Keeping the machine clean reduces the risk of defects in printed products and minimizes downtime caused by breakdowns. Second, invest in training for your operators. Well-trained staff will operate the machinery more effectively, leading to higher productivity and reduced waste. Additionally, ensure that you're using high-quality materials that are compatible with your machine. The choice of substrates, inks, and coatings can significantly influence the final output. Implementing proper storage conditions for these materials helps maintain their integrity. Lastly, continuously monitor production data and make necessary adjustments to optimize processes. Employing a systematic approach to feedback can help identify areas for improvement and innovations, ensuring that your flexo printing operations remain competitive in a global market. By following these tips, businesses can maximize the performance and reliability of their paper flexo Printing Machines.

10 Essential Tips For Paper Flexo Printing Machine Guarantees Peak Performance Is The Best

| Tip | Description | Frequency | Importance Level |

|---|---|---|---|

| Regular Maintenance | Perform routine checks on the machine to ensure optimal performance. | Monthly | High |

| Proper Cleaning | Clean printing plates and cylinders regularly to maintain print quality. | Weekly | High |

| Check Ink Viscosity | Monitor and adjust ink viscosity for better transfer and print quality. | Daily | Medium |

| Optimize Printing Speed | Adjust printing speed based on material and ink type to avoid defects. | Per Job | High |

| Calibration of Tension | Ensure proper substrate tension to avoid misalignment and distortion. | Weekly | High |

| Training Operators | Provide regular training for operators to handle the machine effectively. | Annually | High |

| Monitor Environmental Factors | Check humidity and temperature as they affect ink performance. | Daily | Medium |

| Use Quality Materials | Select high-quality substrates and inks for better results. | Every Job | High |

| Record Keeping | Maintain records of maintenance and production for performance tracking. | Continuous | Medium |

| Regular Equipment Updates | Stay informed about the latest equipment and technology upgrades. | As Needed | Low |

Best Ways To Paper Flexo Printing Machine Products Custom Solutions,

O

Olivia Martinez

The product exceeded my expectations in quality. The after-sales service team demonstrated remarkable expertise and dedication.

18 September 2025

L

Liam White

What a fantastic item! The after-sales representatives were prompt and well-informed, making the process smooth.

11 September 2025

E

Ella Thomas

High-quality materials and impeccable craftsmanship. Customer service representatives were knowledgeable and friendly.

03 August 2025

J

Jack Garcia

Very impressive quality! The after-sales support team was well-informed and very helpful throughout.

01 September 2025

V

Victoria Rivera

Fantastic quality! The after-sales service was incredibly responsive, with staff who really know their product well.

07 September 2025

J

John Miller

Excellent product quality! The support staff was not only friendly but also highly professional, making my experience seamless and enjoyable.

09 August 2025