Contact immediately

Contact immediately Top Custom Printing and Cutting Services from Trusted Suppliers

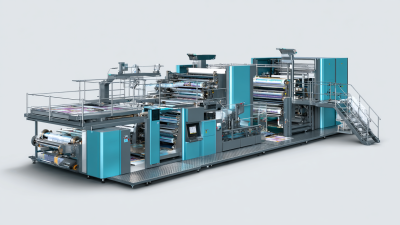

When searching for reliable printing and cutting solutions, Wenzhou Jinyuan Mechanical Technology Co., Ltd. stands out with their exceptional offerings tailored for custom projects. As a manufacturer and supplier, they prioritize quality and precision. Their state-of-the-art Printing Cutting Machinery is designed to meet a wide range of industry needs. With a strong focus on customization, they provide the exact specifications required to optimize production processes. Their machines are built for durability and efficiency, making them perfect for businesses aiming to enhance output. Collaborating with a trusted supplier like Wenzhou Jinyuan not only ensures access to high-quality products but also expert support and service. For those in need of advanced printing and cutting solutions, Wenzhou Jinyuan is an excellent choice to elevate operational capabilities.

Best Practices For Printing Cutting For the Current Year Service Backed by Expertise

In the fast-evolving landscape of slitting and rewinding equipment, staying ahead of the competition requires not only advanced technology but also an understanding of best practices in Printing Cutting. This year, businesses are focused on streamlining production processes while ensuring quality output. To achieve this, integrating automated solutions that provide precision and efficiency is crucial. Companies are increasingly turning to equipment that not only meets current production demands but can also adapt to future needs, ensuring a long-term investment. One of the key best practices in Printing Cutting is the importance of customization. Each production environment has unique requirements, and equipment must be tailored to meet those specific needs. By aligning machinery with actual production workflows, companies can enhance operational efficiency and improve product quality. Furthermore, investing in user-friendly solutions can reduce training time for operators and lead to fewer errors on the cutting line, ultimately resulting in cost savings and improved turnaround times. Additionally, leveraging expertise in equipment selection and deployment is essential. Partnering with experienced professionals who understand the nuances of slitting and rewinding processes can guide businesses in optimizing their setups. Continuous training and support not only enhance staff skills but also facilitate troubleshooting and maintenance, ensuring that machinery remains in peak condition. As the printing industry continues to advance, prioritizing these best practices will help companies navigate challenges while maximizing their production capabilities.

Best Practices For Printing Cutting For the Current Year Service Backed by Expertise

| Best Practice | Description | Importance Level | Expert Recommendations |

|---|---|---|---|

| Material Selection | Choose high-quality materials suitable for the intended use. | High | Utilize samples for testing before full production runs. |

| Precision Cutting | Ensure cuts are precise to avoid waste and misalignment. | High | Regularly calibrate Cutting Machines and conduct routine checks. |

| Design Software Optimization | Use updated software tools for layout and design. | Medium | Stay current with software updates and training. |

| Workflow Efficiency | Streamline processes from design to cutting. | Medium | Implement lean practices to reduce waste. |

| Safety Protocols | Adhere to safety standards to ensure staff well-being. | High | Regular training and safety drills are essential. |

The Ultimate Guide to Printing Cutting Manufacturers You Can Rely On Supplier

M

Madison Lee

Absolutely satisfied with my purchase! The after-sales service was professional and dependable.

02 September 2025

H

Henry Taylor

A remarkable product! The after-sales team was incredibly responsive and provided great assistance.

27 August 2025

I

Isabella Garcia

I love the quality of this item! The support representatives are highly skilled and made my experience smooth.

12 September 2025

A

Ava Hernandez

Superb quality! The follow-up service was incredible, and the staff’s expertise is noteworthy. Very satisfied!

28 September 2025

M

Madison Gordon

Fantastic product quality! The support staff was incredibly professional and very supportive.

10 September 2025

L

Linda Thomas

Amazing product! The quality is exceptional, and the after-sales service was provided by highly skilled personnel.

17 August 2025