Contact immediately

Contact immediately

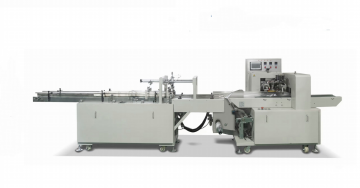

Round-to-round die-cutting and slitting integrated machine

Round-to-Round Die-Cutting and Slitting Integrated Machine

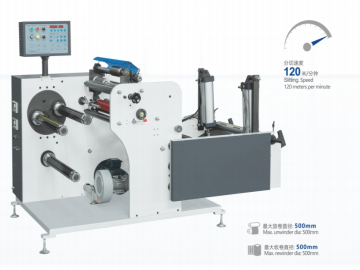

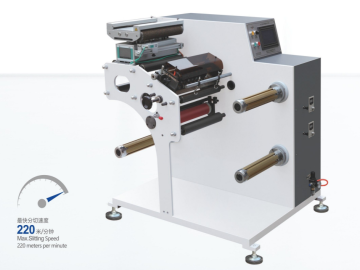

The Round-to-Round Die-Cutting and Slitting Integrated Machine is a high-speed precision converting solution that combines die-cutting and slitting in a single continuous process. Designed for labels, adhesive tapes, electronic films, and packaging materials, it offers exceptional efficiency, accuracy, and stability for mass production.

Key Features:

-

Integrated die-cutting & slitting: Combines two processes in one machine, improving productivity and reducing material handling.

-

High precision cutting: Circular-to-circular cutting ensures consistent pressure and smooth edges, with accuracy up to ±0.1 mm.

-

Servo-driven control: Advanced servo system with PLC touch screen enables precise positioning and real-time parameter adjustment.

-

Stable web tension: Automatic tension control guarantees even cutting and prevents material deformation.

-

Flexible adjustment: Supports quick tool change and cutting width adjustment for multiple material types and production needs.

-

Optional modules: Can be equipped with laminating, waste removal, and rewinding functions for complete process automation.

Applications:

-

Self-adhesive label production

-

Electronic insulation and protective film processing

-

Flexible packaging and printing materials

-

Medical and industrial adhesive tape converting

The Round-to-Round Die-Cutting and Slitting Integrated Machine delivers high-speed operation, superior precision, and simplified workflow, making it the ideal choice for modern label and film processing industries.

-

Get in touch

We're Ready To Assist You Anytime